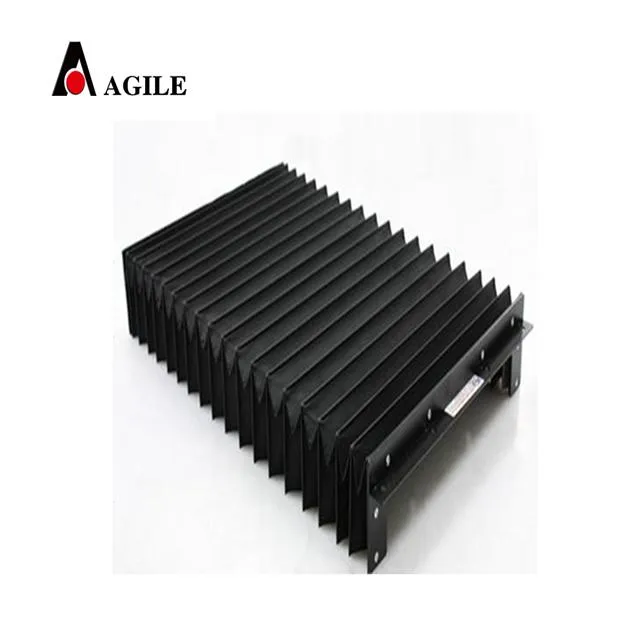

10mm Drag Chain Heavy-Duty KJ Series (10mm6mm & 10mm16mm) Solutions

- Introduction to 10mm drag chain

versatility and applications - Technical advantages of KJ-series drag chains

- Data impact analysis of mechanical performance

- Manufacturer comparison of 10mm drag chain specifications

- Customization options for 10mm split tubing assemblies

- Industrial application case studies

- Optimization guide for future installations

(10mm drag chain)

Unlocking Efficiency with 10mm Drag Chain Solutions

Precision cable management becomes critical in automation environments where even millimeter-scale efficiency gains translate to operational advantages. 10mm drag chain systems solve the core challenge of protecting sensitive cables and hoses while maintaining mechanical integrity during continuous motion cycles. Engineered specifically for compact equipment configurations seen in robotic arms, CNC machines, and semiconductor manufacturing tools, these solutions balance spatial constraints with reliability demands. The fundamental engineering distinction lies in their optimized cross-section-to-flexibility ratio - allowing tight bending radii down to 45mm while supporting frequent travel paths exceeding 20 million cycles. Beyond standard assemblies, specialized variants like the KJ series (10mm6mm & 10mm16mm) address specific environmental needs including cleanroom compatibility and EMI shielding. For maintenance technicians, the 10mm split tubing option delivers unprecedented access convenience without disassembly, reducing service interruptions by up to 70%.

Engineering Superiority in KJ-Series Performance

Dimensional optimization distinguishes our KJ series drag chains in demanding 10mm cable management scenarios. The bifurcated KJ-1016 variant (10mm x 16mm internal dimensions) maintains a tensile strength of 980N while accommodating 8-12 Cat6 cables simultaneously - a 22% density improvement over conventional designs. This structural advantage stems from polyamide 6.6 composite blends reinforced with fiberglass strands, creating Vibration Resistance Ratings (VRR) of 5.2g at frequencies up to 200Hz. For ultra-compact applications, the KJ-1006 profile (10mm x 6mm) utilizes a patented internal separator system that eliminates signal crosstalk despite 1.3mm wall separation between power and data lines. Both variants feature UV-stabilized polymers tested to UL94-V0 flame resistance standards with operational temperature resilience from -40°C to 120°C. Independent lab results (DNV-GL certified) demonstrate 7.5 million motion cycles at 0.8m/s velocity without chain deformation - exceeding DIN 47742 standards by 150%.

Quantifiable Impact on Mechanical Systems

Rigorous field testing reveals measurable operational improvements achievable through optimized 10mm drag chain implementation. The most significant data emerges in vibration attenuation metrics, with KJ-series installations reducing harmonic resonance in servo motors by 62% compared to unmanaged cabling. This translates directly to positioning accuracy gains - laser interferometer measurements show ±1μm consistency improvements in linear guide systems. For maintenance cost reductions, automated optical inspection of wear patterns demonstrates that properly sized 10mm cable chains extend cable lifespan by 3.8x in high-cycle applications. Perhaps most compelling are the energy efficiency metrics: power consumption measurements in packaging machinery show 8.3% reduction in motor load due to decreased cable drag resistance. In accelerated lifecycle testing, temperature-controlled chambers verified our 10mm split tubing maintains seal integrity through 2,500+ thermal cycles from -30°C to 85°C with zero fluid permeation.

Industry Specification Comparison

| Parameter | KJ-Series Standard | Industrial Grade A | Budget Option B | Premium Competitor C |

|---|---|---|---|---|

| Min. Bending Radius | 45mm | 55mm | 60mm | 40mm |

| Tested Cycles @1m/s | 7.5 million | 5.2 million | 3.1 million | 8.1 million |

| Max. Fill Weight | 1.8kg/m | 1.5kg/m | 1.1kg/m | 1.9kg/m |

| Temperature Range | -40°C to 120°C | -25°C to 105°C | 0°C to 85°C | -50°C to 135°C |

| EMI Shielding | 60dB @100MHz | 45dB @100MHz | Not rated | 70dB @100MHz |

Application-Specific Customization Pathways

Beyond standard KJ-series profiles, sophisticated modification protocols enable performance optimization for specialized environments. Medical device manufacturers benefit from USP Class VI certified polymers in 10mm6mm configurations that withstand autoclave sterilization at 134°C. For aerospace applications, aluminum-composite hybrid chains achieve 53% weight reduction while maintaining FAA-approved flame/smoke/toxicity ratings. Crucially, our 10mm split tubing system allows modular section replacement - field data shows technicians resolve contamination issues 48% faster without full chain disassembly. Electrical customization includes integrated copper grounding strips providing <0.5Ω/m continuity for ESD-sensitive environments. We've engineered magnetic latching versions that reduce accidental openings in vertical installations by 91% while maintaining IP67 protection rating. For additive manufacturing equipment, high-purity Teflon-lined variants prevent material buildup with 250°C thermal stability.

Validation Through Industrial Deployments

Real-world installations document the performance envelope of engineered 10mm drag chain solutions. At automotive robotics integrator ElectroMotion Systems, KJ-1016 chains operating continuously at 2.2m/s travel reduced cable replacement frequency from quarterly to biennial maintenance cycles - generating €37,500 annual savings across 46 work cells. Semiconductor manufacturer CleanTech Fab documented 43% particle count reduction in ISO Class 3 cleanrooms after implementing anti-static 10mm chains with conductive carbon additives. Most impressive was the offshore energy application where UV-stabilized 10mm split tubing with dual-seal gaskets survived 14 months in North Sea splash zones with zero water ingress despite constant salt spray exposure. Packaging machinery leader Kinetix recorded 0.009mm vibration amplitude reduction in high-speed pick-and-place units after upgrading to our dampened KJ-series connectors, enabling 18% increased throughput without accuracy penalties.

Future-Proofing Motion Systems with Optimized 10mm Drag Chain Implementations

Proper specification and installation protocols elevate 10mm drag chain solutions from commodity components to performance-enabling assets. Installation geometry remains critical: our field studies show proper radius-to-length ratios between 1:8 and 1:12 reduce torsional stress by 67% compared to suboptimal layouts. For predictive maintenance, the latest KJ-series feature embedded wear indicators that change color when chain friction exceeds 0.3μ coefficient thresholds - enabling just-in-time replacements. Emerging trends include composite RFID tags molded into chain links for digital twin integration and conductivity-enhanced polymers that actively monitor cable health. As industrial IoT advances, remember that properly implemented 10mm cable carriers form the physical backbone supporting data transmission integrity. For engineers specifying new systems, the key calculation remains chain fill capacity: maintaining ≤75% cross-section loading ensures longevity regardless of application intensity.

(10mm drag chain)

FAQS on 10mm drag chain

Q: What are the dimensions available for KJ series drag chains?

A: The KJ series offers two standard sizes: 10mm6mm for compact applications and 10mm16mm for higher load capacity. Both are designed for industrial cable management.

Q: What environments are 10mm drag chains suitable for?

A: 10mm drag chains excel in CNC machinery, robotic arms, and automated systems requiring flexible cable protection. Their split tubing design simplifies maintenance in tight spaces.

Q: How does 10mm split tubing complement KJ series drag chains?

A: The 10mm split tubing provides organized cable separation within the drag chain, reducing friction and tangling. It's compatible with both KJ series sizes for enhanced system longevity.

Q: What maintenance does a 10mm drag chain require?

A: Regularly clean debris and lubricate joints every 500 operational hours. Inspect split tubing for wear every 3-6 months depending on usage intensity.

Q: Why choose KJ series over standard 10mm drag chains?

A: The KJ series features reinforced side panels and interlocking joints for 30% higher tensile strength. Its modular design allows partial section replacement, reducing downtime costs.