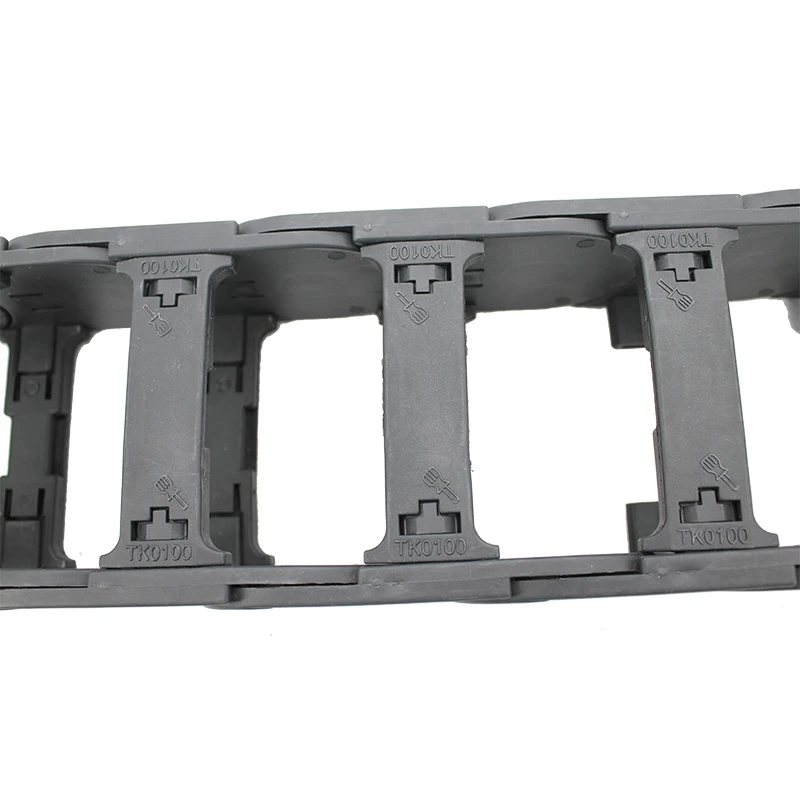

reinforced drag chain

In the bustling world of automation, the 10mm drag chain stands out as a critical component designed to protect and guide flexible cables and hoses connected to moving parts. With its subtle complexity and pivotal role, understanding the various aspects of this unsung hero can significantly enhance both functional performance and system longevity in numerous industrial applications.

Our authoritative insight into drag chains also emphasizes their customization capabilities. Companies can select from open or closed types, dependent on specific operational needs. While open drag chains are ideal when airflow around the cables is necessary, closed chains offer superior protection against external contaminants. The choice between these options allows businesses to tailor their operations for maximum efficiency and safety. Over the years, trustworthiness in drag chain solutions has been underscored by continuous product innovations and compliance with international safety standards. The integration of these chains into system designs often follows rigorous testing and quality assurance protocols which confirm their capability to handle dynamic loads and high-speed operations without compromising the integrity of the carried cables. This standard of excellence is vital for maintaining uninterrupted operations and avoiding costly downtimes. When selecting a 10mm drag chain, it's essential to consider the specific use case scenarios. Factors such as the type and number of cables, bend radius requirements, travel distance, and environmental conditions must all be evaluated meticulously. Our specialist advice underscores the importance of proper installation and maintenance practices, such as regular inspections and tension adjustments, which are crucial for optimized performance and longevity of the drag chains. In conclusion, the 10mm drag chain is more than a mere mechanical conduit in industrial applications. It represents an integration of thoughtful design and engineering excellence tailored to ensure productivity and reliability. As industries continually evolve with advancing technologies, the demand for drag chains that combine compactness with robust performance will remain integral, thus cementing their place in the future of industrial automation. With a clear focus on these elements, businesses can enhance their operational efficiency while safeguarding their critical infrastructures.

Our authoritative insight into drag chains also emphasizes their customization capabilities. Companies can select from open or closed types, dependent on specific operational needs. While open drag chains are ideal when airflow around the cables is necessary, closed chains offer superior protection against external contaminants. The choice between these options allows businesses to tailor their operations for maximum efficiency and safety. Over the years, trustworthiness in drag chain solutions has been underscored by continuous product innovations and compliance with international safety standards. The integration of these chains into system designs often follows rigorous testing and quality assurance protocols which confirm their capability to handle dynamic loads and high-speed operations without compromising the integrity of the carried cables. This standard of excellence is vital for maintaining uninterrupted operations and avoiding costly downtimes. When selecting a 10mm drag chain, it's essential to consider the specific use case scenarios. Factors such as the type and number of cables, bend radius requirements, travel distance, and environmental conditions must all be evaluated meticulously. Our specialist advice underscores the importance of proper installation and maintenance practices, such as regular inspections and tension adjustments, which are crucial for optimized performance and longevity of the drag chains. In conclusion, the 10mm drag chain is more than a mere mechanical conduit in industrial applications. It represents an integration of thoughtful design and engineering excellence tailored to ensure productivity and reliability. As industries continually evolve with advancing technologies, the demand for drag chains that combine compactness with robust performance will remain integral, thus cementing their place in the future of industrial automation. With a clear focus on these elements, businesses can enhance their operational efficiency while safeguarding their critical infrastructures.