1 inch to 4 inch wire loom for efficient cable management and protection solutions

Understanding 1 4 Inch Wire Loom A Comprehensive Guide

When it comes to organizing and protecting wires in various applications, the term wire loom often emerges as a crucial component. Among the various sizes available, the 1 4 inch wire loom stands out, offering a unique balance of flexibility, durability, and functionality. This article will explore what wire loom is, why the 1 4 inch variety is important, and how to effectively implement it in your projects.

What is Wire Loom?

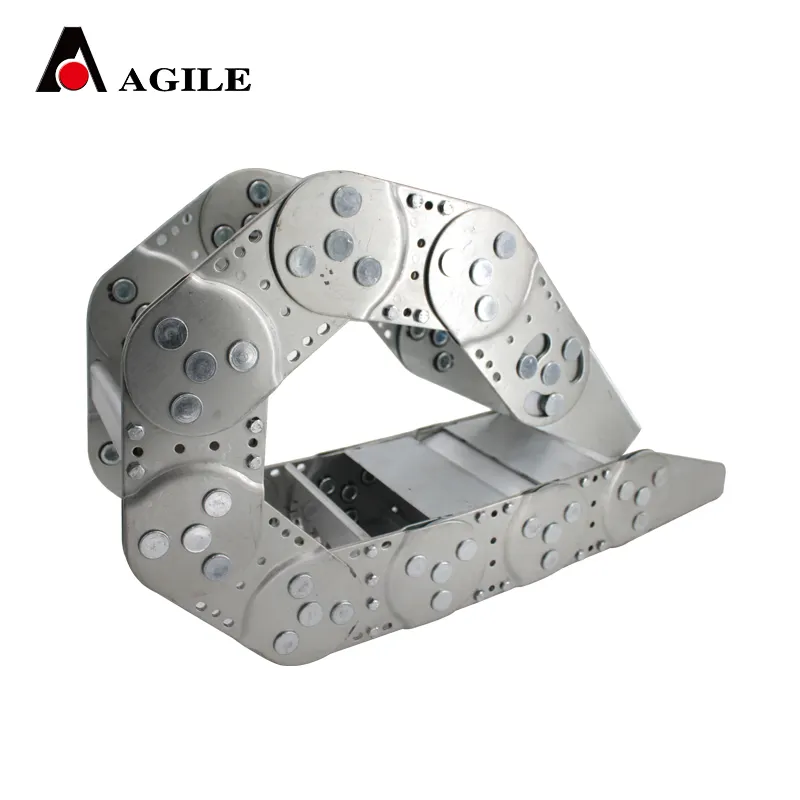

Wire loom, generally referred to as a conduit for wires, is a protective tubing designed to organize and safeguard electrical wires and cables. Made from materials like polyethylene, PVC, or nylon, wire looms serve multiple purposes, including protection from abrasion, environmental damage, and accidental cuts. Wire looms are vital for both commercial and residential applications, ensuring a tidy appearance while also enhancing safety by minimizing the risk of electrical shorts or malfunctions.

Importance of the 1 4 Inch Wire Loom

The designation 1 4 inch refers to the specific diameter of the wire loom. This size is particularly beneficial for a variety of applications due to its versatility

1. Compatibility with Various Wires The 1 4 inch size accommodates a range of wire gauges, making it a popular choice among engineers and DIY enthusiasts. It can handle everything from automotive wiring to home electrical projects.

2. Space Efficiency The 1 4 inch size strikes a balance between compactness and capacity. This makes it ideal for applications where space is limited but organization is essential, such as in automotive interiors or densely packed electrical cabinets.

3. Durable Protection Wire looms in this size often feature robust materials that can withstand high temperatures, chemicals, and UV exposure. This durability is crucial in environments where wires are vulnerable to the elements.

Applications of 1 4 Inch Wire Loom

The applications for 1 4 inch wire loom are extensive and varied

- Automotive Uses In vehicles, wire looms protect wiring harnesses from engine heat and movement. They help prevent wear and tear, which is essential for reliability and longevity.

1 4 inch wire loom

- Industrial Settings Factories and warehouses often use wire loom to bundle together cables and wires in machinery, preventing tangles and reducing the risk of accidents

.- Home Improvement During renovations or electrical upgrades, homeowners often use wire looms to keep wiring neat and organized, enhancing both safety and aesthetics.

- Commercial Electronics In the world of consumer electronics, maintaining clear pathways for wires is essential for both performance and safety. Wire looms are utilized in assembling equipment to ensure wires are properly routed.

Installation Tips

Successfully using 1 4 inch wire loom requires attention to detail and proper technique

1. Measure and Cut Before installation, measure the length of wire you need to cover accurately. Cut the wire loom to the appropriate size, allowing a little extra length for connectors.

2. Route Carefully When applying the loom, carefully route it along the desired path. This minimizes bends and twists that can lead to wear over time.

3. Secure in Place Use clips, zip ties, or adhesive tape to secure the loom in place, making sure it doesn’t move or shift during operation.

4. Monitor Conditions If the wires are subject to high heat, ensure the loom material is rated for such exposure. Regularly inspect for signs of wear to prevent potential hazards.

Conclusion

The 1 4 inch wire loom is more than just a simple component; it’s an essential aspect of ensuring the safety and longevity of wiring in various applications. By understanding its benefits and applications, users can implement this versatile solution effectively. Whether you're working in automotive, industrial, or home environments, investing in quality wire loom can prevent future headaches and enhance the reliability of your electrical systems.