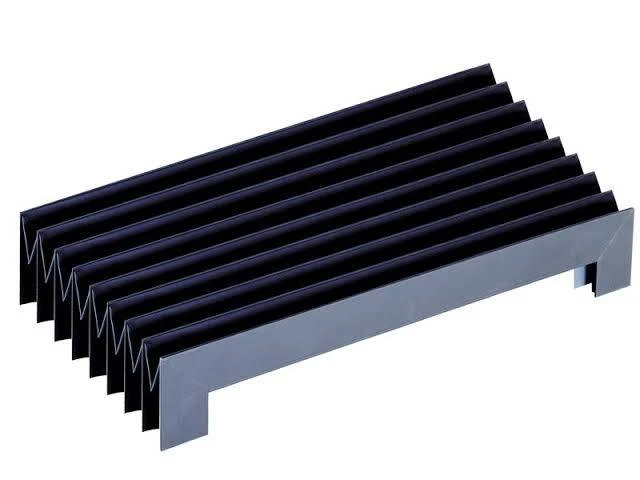

corrugated wire loom

Wire looms are essential components in organizing and protecting electrical wiring in various settings, from automotive to home and office environments. The 1 4 split wire loom offers unique benefits in terms of management and functionality, catering to both professional and DIY audiences looking to streamline their wiring systems.

Wire loom installation is straightforward, yet it benefits from a few best practices to maximize results. First, ensure all wires are clean and free from dust before insertion into the loom to facilitate smooth installation and prevent potential damage. When dealing with longer sections, recruit an extra pair of hands to maintain tension on the loom as wires are being fed through, preventing kinks and ensuring an even protective wrap. Regular maintenance checks are advisable to ensure that the loom remains secure and is providing optimal protection, especially in high-vibration or variable temperature environments. In terms of sourcing the 1 4 split wire loom, choosing a reputable supplier is critical. Reviews and industry testimonials provide insights into the product quality and customer service of potential suppliers. Ensure the supplier adheres to relevant industry standards and offers warranties or guarantees, which can be a further assurance of their commitment to quality. Establishing a relationship with a reliable supplier can provide ongoing benefits, such as expert advice tailored to your specific applications and potential discounts on bulk purchases. In conclusion, the 1 4 split wire loom is an invaluable tool for anyone involved in extensive wiring projects. Its blend of practicality, protection, and aesthetic appeal makes it a preferred choice among professionals and hobbyists alike. By focusing on strategic installation and maintenance, and sourcing from trusted suppliers, users can maximize the benefits of this component, achieving both immediate project needs and long-term reliability. Make informed choices about wire management to ensure that your projects stand out in quality and performance.

Wire loom installation is straightforward, yet it benefits from a few best practices to maximize results. First, ensure all wires are clean and free from dust before insertion into the loom to facilitate smooth installation and prevent potential damage. When dealing with longer sections, recruit an extra pair of hands to maintain tension on the loom as wires are being fed through, preventing kinks and ensuring an even protective wrap. Regular maintenance checks are advisable to ensure that the loom remains secure and is providing optimal protection, especially in high-vibration or variable temperature environments. In terms of sourcing the 1 4 split wire loom, choosing a reputable supplier is critical. Reviews and industry testimonials provide insights into the product quality and customer service of potential suppliers. Ensure the supplier adheres to relevant industry standards and offers warranties or guarantees, which can be a further assurance of their commitment to quality. Establishing a relationship with a reliable supplier can provide ongoing benefits, such as expert advice tailored to your specific applications and potential discounts on bulk purchases. In conclusion, the 1 4 split wire loom is an invaluable tool for anyone involved in extensive wiring projects. Its blend of practicality, protection, and aesthetic appeal makes it a preferred choice among professionals and hobbyists alike. By focusing on strategic installation and maintenance, and sourcing from trusted suppliers, users can maximize the benefits of this component, achieving both immediate project needs and long-term reliability. Make informed choices about wire management to ensure that your projects stand out in quality and performance.