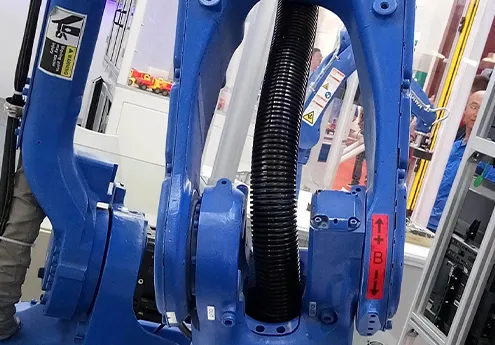

1.5 inch wire loom

When it comes to optimizing electrical systems, ensuring safety and organization are paramount. The 1.5-inch wire loom stands as an essential tool for those serious about maintaining both the functionality and protection of their wiring systems. Understanding the nuances and advantages of using a 1.5-inch wire loom transforms how you approach wire management in various settings.

The security provided by a 1.5-inch wire loom is not limited to cables' physical protection. From an electrical standpoint, organizing wires into a single pathway reduces electromagnetic interference (EMI). For those venturing into setting up detailed home theater systems or complex sound setups, minimizing EMI is crucial. By using a wire loom, audiophiles and tech aficionados can ensure a clearer, crisper sound output with minimal noise interference. Expertise in using a 1.5-inch wire loom extends to its material options. Choosing the right material for your specific application is vital. For example, Polyethylene (PE) looms are excellent for general applications, providing a balance between flexibility and durability. Meanwhile, materials such as Nylon and polyethylene terephthalate (PET) offer enhanced resistance against higher temperatures or chemicals, suitable for extreme environments. Those who rely on authoritative products will appreciate that 1.5-inch wire looms, when purchased from reputable manufacturers, comply with industry standards such as ISO certifications and safety regulations. Such assurances translate into reliability and trustworthiness in any professional setting, be it industrial, commercial, or residential. The installation process of a 1.5-inch wire loom, while manageable, requires attention to detail. Begin by measuring the length of the wires needing organization. Cut the loom to the desired size using a sharp crafting knife for precision or specialized wire loom tools available in the market. Upon completion, gently insert the wires into the loom, ensuring a snug fit. For additional security, use cable ties or loom clamps at intervals to prevent slippage and maintain neatness. In conclusion, the implementation of a 1.5-inch wire loom is an investment in both functionality and safety. Its multi-faceted applications across various industries underscore its indispensability for professionals and hobbyists alike. By choosing the right material and understanding its applications, you harness a solution that champions protection, organization, and aesthetic finesse. The 1.5-inch wire loom is not just a protective cover—it's the bridge between efficiency and safety in modern wire management.

The security provided by a 1.5-inch wire loom is not limited to cables' physical protection. From an electrical standpoint, organizing wires into a single pathway reduces electromagnetic interference (EMI). For those venturing into setting up detailed home theater systems or complex sound setups, minimizing EMI is crucial. By using a wire loom, audiophiles and tech aficionados can ensure a clearer, crisper sound output with minimal noise interference. Expertise in using a 1.5-inch wire loom extends to its material options. Choosing the right material for your specific application is vital. For example, Polyethylene (PE) looms are excellent for general applications, providing a balance between flexibility and durability. Meanwhile, materials such as Nylon and polyethylene terephthalate (PET) offer enhanced resistance against higher temperatures or chemicals, suitable for extreme environments. Those who rely on authoritative products will appreciate that 1.5-inch wire looms, when purchased from reputable manufacturers, comply with industry standards such as ISO certifications and safety regulations. Such assurances translate into reliability and trustworthiness in any professional setting, be it industrial, commercial, or residential. The installation process of a 1.5-inch wire loom, while manageable, requires attention to detail. Begin by measuring the length of the wires needing organization. Cut the loom to the desired size using a sharp crafting knife for precision or specialized wire loom tools available in the market. Upon completion, gently insert the wires into the loom, ensuring a snug fit. For additional security, use cable ties or loom clamps at intervals to prevent slippage and maintain neatness. In conclusion, the implementation of a 1.5-inch wire loom is an investment in both functionality and safety. Its multi-faceted applications across various industries underscore its indispensability for professionals and hobbyists alike. By choosing the right material and understanding its applications, you harness a solution that champions protection, organization, and aesthetic finesse. The 1.5-inch wire loom is not just a protective cover—it's the bridge between efficiency and safety in modern wire management.