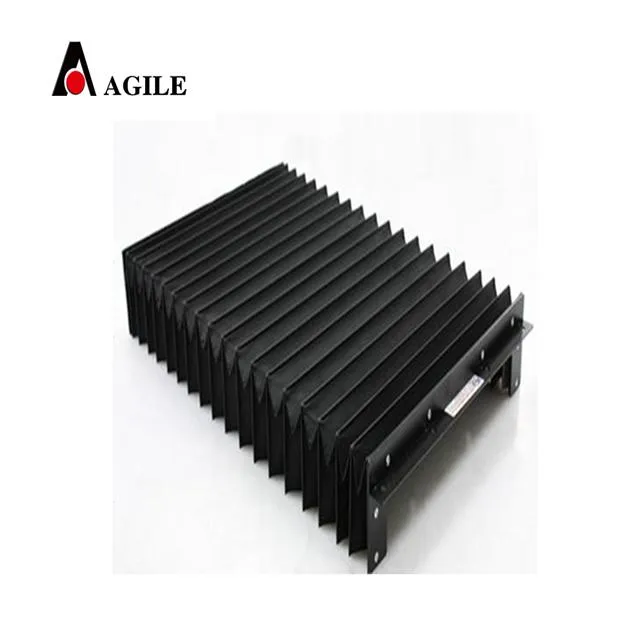

nylon flexible wire loom corrugated bellow conduit hose pipe

In the world of automotive and electrical installations, the term 1 in wire loom plays a pivotal role, especially for professionals who prioritize efficiency and reliability in their projects. Wire looms are essential components, organizing and protecting wiring harnesses in a variety of applications. Understanding their significance can make all the difference in both performance and safety.

Additionally, securing the wire loom with appropriate clips or fasteners enhances its protective capabilities. Loose wires can become a hazard, not only risking electrical faults but also compromising the safety of the installation. Ensuring that the 1-inch loom is tightly secured not only enhances the appearance but also provides peace of mind that the system is safe and operational. Beyond practical knowledge, it’s important to consider authoritativeness when selecting suppliers or manufacturers of wire looms. Reputable brands demonstrate their commitment to quality through certifications and adherence to industry standards. This doesn't just ensure compliance but also boosts confidence that the wire loom will perform as expected over its lifespan. One should not overlook the trustworthiness factor, which often hinges on reviews and user experiences. Professionals share insights into their experiences with specific brands and products, highlighting both strengths and potential issues. Engaging with these reviews provides valuable context for making informed decisions that go beyond technical specifications. The practicality of wire looms extends to aesthetics, often overlooked in technical discussions. A well-organized wiring system not only functions better but also looks professional and considered. This is particularly important in customer-facing applications where the appearance can impact perceptions of quality and attention to detail. In conclusion, the role of a 1-inch wire loom in any wiring project cannot be overstated. Its combination of practicality, protective capabilities, and efficient installation is invaluable for professionals tasked with ensuring the reliability and safety of electrical systems. By ensuring thorough project planning, selecting reputable sources, and adopting best installation practices, one can leverage the full potential of wire looms to achieve robust, aesthetically pleasing, and safe wiring solutions.

Additionally, securing the wire loom with appropriate clips or fasteners enhances its protective capabilities. Loose wires can become a hazard, not only risking electrical faults but also compromising the safety of the installation. Ensuring that the 1-inch loom is tightly secured not only enhances the appearance but also provides peace of mind that the system is safe and operational. Beyond practical knowledge, it’s important to consider authoritativeness when selecting suppliers or manufacturers of wire looms. Reputable brands demonstrate their commitment to quality through certifications and adherence to industry standards. This doesn't just ensure compliance but also boosts confidence that the wire loom will perform as expected over its lifespan. One should not overlook the trustworthiness factor, which often hinges on reviews and user experiences. Professionals share insights into their experiences with specific brands and products, highlighting both strengths and potential issues. Engaging with these reviews provides valuable context for making informed decisions that go beyond technical specifications. The practicality of wire looms extends to aesthetics, often overlooked in technical discussions. A well-organized wiring system not only functions better but also looks professional and considered. This is particularly important in customer-facing applications where the appearance can impact perceptions of quality and attention to detail. In conclusion, the role of a 1-inch wire loom in any wiring project cannot be overstated. Its combination of practicality, protective capabilities, and efficient installation is invaluable for professionals tasked with ensuring the reliability and safety of electrical systems. By ensuring thorough project planning, selecting reputable sources, and adopting best installation practices, one can leverage the full potential of wire looms to achieve robust, aesthetically pleasing, and safe wiring solutions.