nylon flexible wire loom corrugated bellow conduit hose pipe

2 split loom is a versatile protective tubing solution that caters to a myriad of industries, including automotive, industrial, and technology sectors. The demand for durable and efficient wire management solutions has skyrocketed, pushing 2 split loom to the forefront due to its myriad benefits and applications.

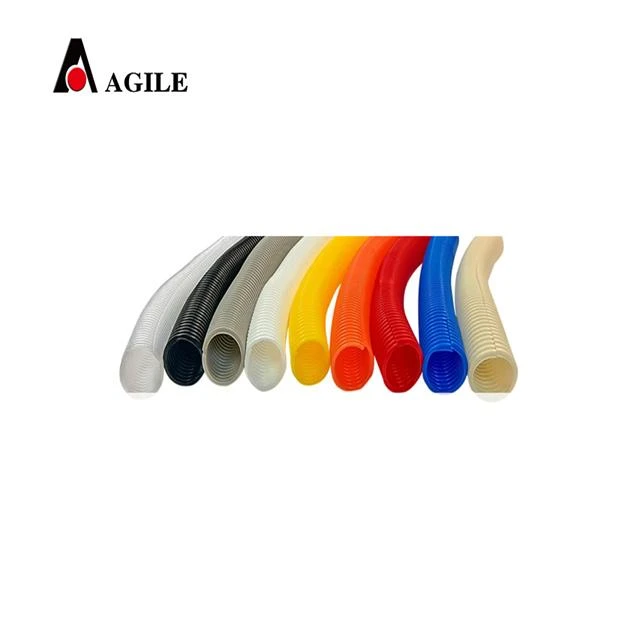

Adopting 2 split loom also aligns well with sustainability goals. Proper wire management leads to fewer material replacements and repairs. By extending the life of existing hardware and reducing waste, companies can achieve their sustainability targets more effectively, while simultaneously enjoying reduced expenditure on repair and maintenance. The best practices in selecting a quality 2 split loom encompass considering the material composition, flexibility, and durability. Common materials include polyethylene and nylon. Polyethylene is celebrated for its lightweight nature and resistance to most chemicals, making it an excellent choice for general applications. On the other hand, nylon provides superior strength and thermal resistance, fitting for more demanding environments. Additionally, color-coding capabilities offered by 2 split loom products cannot be overstated. Various colors can segment and differentiate sections of wiring systems, allowing for easier identification and troubleshooting. This is particularly helpful during maintenance or emergency repairs, where time is of the essence. To capitalize fully on the features offered by 2 split loom tubing, industry professionals often pursue solutions from reputable manufacturers, sourcing products that adhere to stringent quality standards. This assurance of quality not only translates into better performance and longevity but also engenders trust from stakeholders — be it end-users, customers, or partners. Ultimately, the performance-enhancing advantages and adaptability of the 2 split loom position it as a premier choice in the realm of wire management solutions. For any business or individual dealing in complex wiring systems, investing in a reliable split loom tubing means investing in consistent performance and peace of mind. The reassurance that wires are well-protected and organized provides a solid foundation upon which companies can build dependable technological infrastructures.

Adopting 2 split loom also aligns well with sustainability goals. Proper wire management leads to fewer material replacements and repairs. By extending the life of existing hardware and reducing waste, companies can achieve their sustainability targets more effectively, while simultaneously enjoying reduced expenditure on repair and maintenance. The best practices in selecting a quality 2 split loom encompass considering the material composition, flexibility, and durability. Common materials include polyethylene and nylon. Polyethylene is celebrated for its lightweight nature and resistance to most chemicals, making it an excellent choice for general applications. On the other hand, nylon provides superior strength and thermal resistance, fitting for more demanding environments. Additionally, color-coding capabilities offered by 2 split loom products cannot be overstated. Various colors can segment and differentiate sections of wiring systems, allowing for easier identification and troubleshooting. This is particularly helpful during maintenance or emergency repairs, where time is of the essence. To capitalize fully on the features offered by 2 split loom tubing, industry professionals often pursue solutions from reputable manufacturers, sourcing products that adhere to stringent quality standards. This assurance of quality not only translates into better performance and longevity but also engenders trust from stakeholders — be it end-users, customers, or partners. Ultimately, the performance-enhancing advantages and adaptability of the 2 split loom position it as a premier choice in the realm of wire management solutions. For any business or individual dealing in complex wiring systems, investing in a reliable split loom tubing means investing in consistent performance and peace of mind. The reassurance that wires are well-protected and organized provides a solid foundation upon which companies can build dependable technological infrastructures.