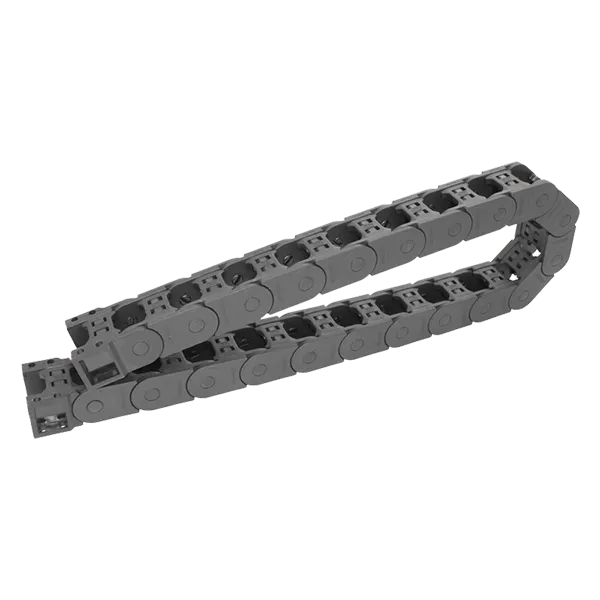

nylon flexible wire loom corrugated bellow conduit hose pipe

In the intricate world of electrical wiring and cable management, the term [3 4 wire loom] has emerged as a pivotal component for both DIY enthusiasts and seasoned professionals. Across various industries, the adoption of wire looms has soared, owing to their ability to organize, protect, and streamline wires in a multitude of applications.

From a professional standpoint, choosing the right material for your wire loom is essential. Polyethylene and polypropylene are commonly favored for general applications due to their flexibility and durability. However, for more specific uses, such as in high-temperature engine bays or industrial environments, materials like nylon or even metalized looms may offer superior resilience. Moreover, the installation process itself can profoundly influence the overall efficiency and durability of the wire loom system. Tools like split loom insertion tools can greatly facilitate the installation process, providing a seamless experience that saves valuable time and effort, particularly in more extensive, complex projects. Ensuring connectors and splices within the loom are secure is also critical for maintaining the integrity of the wiring configuration. Reflecting on real-world experience, one consistently reported benefit of a well-selected and expertly installed wire loom configuration is the reduction in downtime related to wire and cable management issues. For businesses and industries that rely heavily on continuous operation, such as manufacturing or telecommunications, the investment in high-quality loom solutions translates directly into operational efficiency and reduced maintenance costs. To conclude, in the domain of cable management, the 3 to 4 wire loom stands as a testament to the marriage of simplicity and effectiveness. When optimized in terms of material, size, and shielding, these looms provide a robust solution to the often complex challenge of wire organization and protection. As more users—be they amateur hobbyists or skilled professionals—recognize the benefits of utilizing wire looms, the demand for refined, durable, and efficient wiring solutions is only expected to grow steadily across diverse sectors.

From a professional standpoint, choosing the right material for your wire loom is essential. Polyethylene and polypropylene are commonly favored for general applications due to their flexibility and durability. However, for more specific uses, such as in high-temperature engine bays or industrial environments, materials like nylon or even metalized looms may offer superior resilience. Moreover, the installation process itself can profoundly influence the overall efficiency and durability of the wire loom system. Tools like split loom insertion tools can greatly facilitate the installation process, providing a seamless experience that saves valuable time and effort, particularly in more extensive, complex projects. Ensuring connectors and splices within the loom are secure is also critical for maintaining the integrity of the wiring configuration. Reflecting on real-world experience, one consistently reported benefit of a well-selected and expertly installed wire loom configuration is the reduction in downtime related to wire and cable management issues. For businesses and industries that rely heavily on continuous operation, such as manufacturing or telecommunications, the investment in high-quality loom solutions translates directly into operational efficiency and reduced maintenance costs. To conclude, in the domain of cable management, the 3 to 4 wire loom stands as a testament to the marriage of simplicity and effectiveness. When optimized in terms of material, size, and shielding, these looms provide a robust solution to the often complex challenge of wire organization and protection. As more users—be they amateur hobbyists or skilled professionals—recognize the benefits of utilizing wire looms, the demand for refined, durable, and efficient wiring solutions is only expected to grow steadily across diverse sectors.