3 4 wire loom

Understanding 3% and 4% Wire Looms and Their Applications

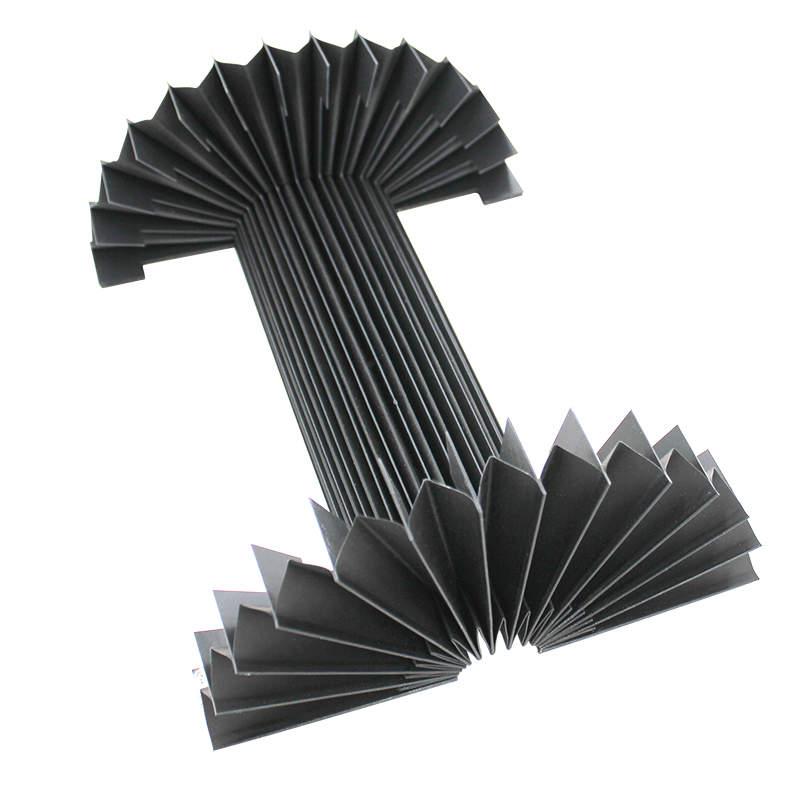

Wire loom is a crucial component in the organization and protection of wiring in various applications, particularly in automotive, aerospace, and electronic sectors. The terms 3% wire loom and 4% wire loom often refer to different types or specifications of wire looms that serve specific needs based on the wiring configuration and environmental factors.

What is Wire Loom?

Wire loom, commonly made from materials such as polyethylene or nylon, is designed to bundle multiple wires or cables together while providing insulation and mechanical protection. This not only helps to prevent wear and tear from abrasion but also shields the wires from heat, moisture, and chemicals. In automotive settings, wire looms are essential for maintaining the integrity of electrical systems, ensuring that wires do not become tangled or damaged.

The Role of 3% and 4% in Wire Looms

The percentages in 3% wire loom and 4% wire loom typically refer to specific performance characteristics or the material composition of the looms. For instance, these percentages might indicate the amount of a particular additive or the UV resistance level in the plastic used, which directly influences the loom's durability and suitability for specific environments.

- 3% Wire Loom A wire loom classified as 3% may offer a balanced level of flexibility and resistance to environmental factors. This type is often ideal for standard applications where moderate protection is needed without the risks associated with extreme conditions.

3 4 wire loom

- 4% Wire Loom Conversely, a 4% wire loom might incorporate additional protective elements, making it more resilient to harsh chemicals, higher temperatures, or exposure to UV rays. This enhanced durability makes it suitable for use in more demanding environments, such as under the hood of a vehicle or in industrial machinery.

Applications and Benefits

One of the primary benefits of using wire looms, whether 3% or 4%, is the ease of installation and management they provide. By grouping wires together, users can manage complex wiring systems more efficiently. In automotive applications, for instance, well-organized wiring not only improves aesthetics but also reduces the risk of electrical failures caused by abrasion or exposure.

Moreover, wire looms can also contribute to safety standards by minimizing the chances of short circuits, which can arise from exposed wires. By opting for a wire loom that matches the specific requirements of the wiring system—considering factors like flexibility, environmental exposure, and mechanical protection—users can ensure a reliable and long-lasting solution.

Conclusion

In summary, the choice between 3% and 4% wire loom should be guided by the specific needs of the project at hand. Understanding the characteristics and advantages of each type allows for more informed decisions, leading to better protection and organization of electrical systems across various applications. As technology continues to evolve, the importance of such components in maintaining the integrity and functionality of complex wiring systems remains paramount.