3 8 convoluted tubing

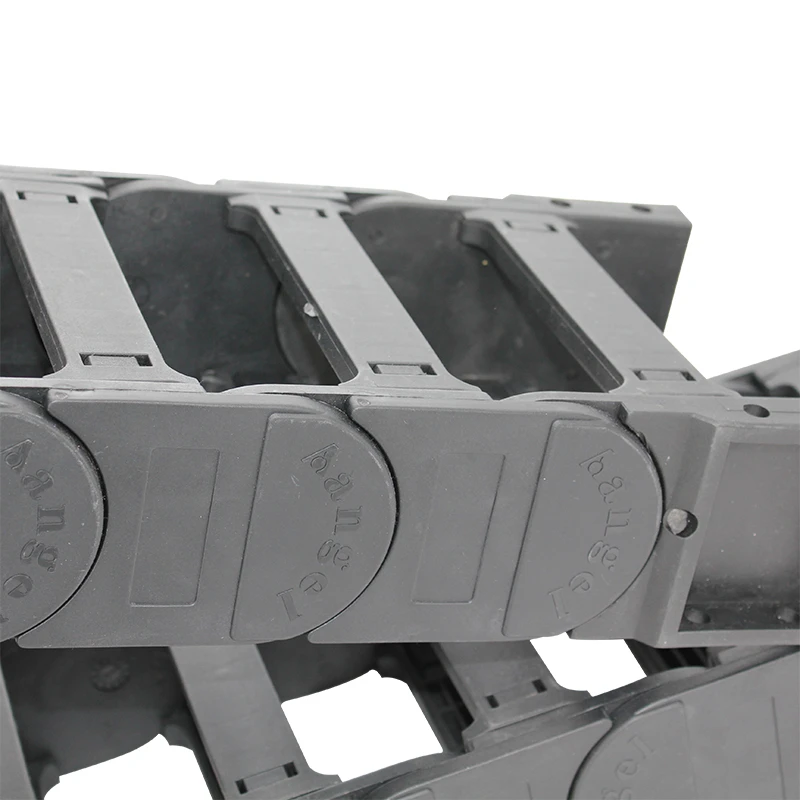

Convoluted tubing, often referred to by part numbers like 3 8 convoluted tubing, represents a critical component in many industrial and consumer applications. This versatile product is prized for its unique design and practical benefits, serving a necessary role in industries ranging from automotive to aerospace and beyond.

Establishing the authority of 3/8 convoluted tubing within your operations hinges on recognizing the advantages it presents over alternative solutions. Compared to split loom tubing or other protective coverings, convoluted tubing offers superior abrasion protection. Its design naturally safeguards against cuts and tears, ensuring the long-term reliability of your wiring systems. Trustworthiness in this product is partly attained through reputable manufacturers and rigorous standards testing. Original equipment manufacturers (OEMs) in competitive fields often employ convoluted tubing that has been thoroughly vetted and certified for use in critical applications. Third-party certifications can further assert the tubing's quality, offering peace of mind that it will perform as expected under demanding conditions. Investing in high-quality 3/8 convoluted tubing not only protects equipment but also enhances the operational lifespan of electrical systems. By choosing a product that is well-researched and extensively tested, you align your enterprise with proven industry best practices. This choice reflects a commitment to quality and reliability that benefits both the company and its clients. In conclusion, understanding the nuances and merits of 3/8 convoluted tubing empowers industries to make informed choices about their protective wiring needs. Its application stands as a testament to engineering excellence, combining flexibility, strength, and safety in a single versatile solution. Embracing this tubing as part of standard practice can lead to improvements in both product performance and safety benchmarks, ensuring continued success and innovation.

Establishing the authority of 3/8 convoluted tubing within your operations hinges on recognizing the advantages it presents over alternative solutions. Compared to split loom tubing or other protective coverings, convoluted tubing offers superior abrasion protection. Its design naturally safeguards against cuts and tears, ensuring the long-term reliability of your wiring systems. Trustworthiness in this product is partly attained through reputable manufacturers and rigorous standards testing. Original equipment manufacturers (OEMs) in competitive fields often employ convoluted tubing that has been thoroughly vetted and certified for use in critical applications. Third-party certifications can further assert the tubing's quality, offering peace of mind that it will perform as expected under demanding conditions. Investing in high-quality 3/8 convoluted tubing not only protects equipment but also enhances the operational lifespan of electrical systems. By choosing a product that is well-researched and extensively tested, you align your enterprise with proven industry best practices. This choice reflects a commitment to quality and reliability that benefits both the company and its clients. In conclusion, understanding the nuances and merits of 3/8 convoluted tubing empowers industries to make informed choices about their protective wiring needs. Its application stands as a testament to engineering excellence, combining flexibility, strength, and safety in a single versatile solution. Embracing this tubing as part of standard practice can lead to improvements in both product performance and safety benchmarks, ensuring continued success and innovation.