Exploring the Benefits and Applications of 3% 208% Convoluted Tubing in Various Industries

Understanding 3 8% Convoluted Tubing An Overview

Convoluted tubing is an essential component widely used across various industries, particularly in applications requiring flexibility, durability, and protection for wires and cables. Among the various specifications in the market, the 3 8% convoluted tubing stands out due to its unique properties and functionality. This article explores the characteristics, applications, and advantages of 3 8% convoluted tubing.

What is Convoluted Tubing?

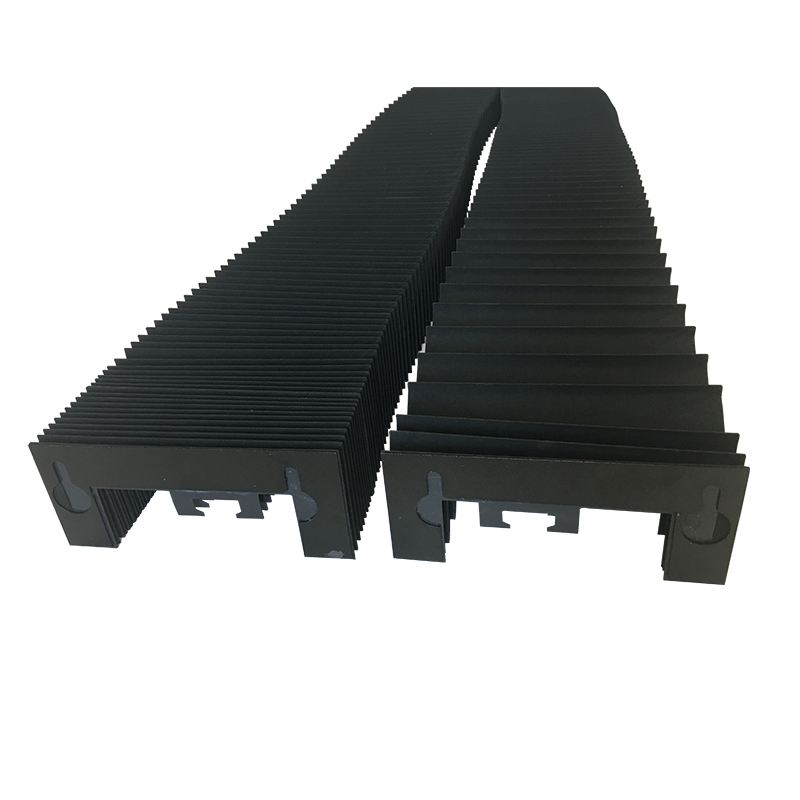

Convoluted tubing is a type of protective covering designed to secure and organize wires and cables. Its primary feature is a series of ridges or convolutions along its length, providing enhanced flexibility compared to traditional tubing. This flexibility allows for easy maneuverability in tight spaces, making it ideal for applications in automotive, aerospace, medical, and industrial environments.

Characteristics of 3 8% Convoluted Tubing

The designation 3 8% typically refers to specific material compositions and certain percentage characteristics that define the tubing’s performance under different conditions. A crucial aspect is the structural integrity, typically characterized by percent elongation, tensile strength, and temperature resistance which indicates how well the tubing can maintain its integrity under mechanical stress and high temperatures.

For instance, a tubing specification might indicate that it is made from high-quality polyethylene or nylon, offering a balance between rigidity and flexibility. This chemical makeup contributes to the tubing’s ability to resist wear and tear, making it suitable for environments susceptible to abrasion and mechanical damage.

Applications of 3 8% Convoluted Tubing

3 8 convoluted tubing

3 8% convoluted tubing finds applications in various sectors due to its protective qualities. In the automotive industry, it is commonly used to protect wiring harnesses from heat, moisture, and physical damage. The aerospace sector benefits from this tubing as well, where it safeguards critical wires within aircraft from environmental hazards.

In the medical field, it is used for encasing sensors and cables in devices that are exposed to harsh sterilization processes. Similarly, in industrial settings, the tubing protects instrumentation cables and controls from the harsh operational environment, ensuring uninterrupted functionality while enhancing safety against exposure risks.

Advantages of 3 8% Convoluted Tubing

The advantages of using 3 8% convoluted tubing are numerous. Its unique design allows for excellent flexibility, enabling installations in restricted spaces without compromising the protection of the cables inside. This tubing is resistant to various environmental conditions, including chemicals and UV degradation, making it ideal for outdoor applications.

Moreover, the convoluted design helps manage airflow, enhancing cooling properties in environments where heat dissipation is crucial. Another benefit is its lightweight nature, which reduces the overall weight of cabling systems, an important consideration in aerospace and automotive designs where weight-saving is critical.

Conclusion

In summary, 3 8% convoluted tubing serves as a vital solution for protecting and organizing wires and cables across multiple industries. Its flexibility, durability, and resistance to environmental factors make it an unmatched choice for applications where performance is paramount. As technology advances, the demand for high-quality convoluted tubing like the 3 8% variant will likely continue to rise, enabling improvements in safety and efficiency across various sectors.