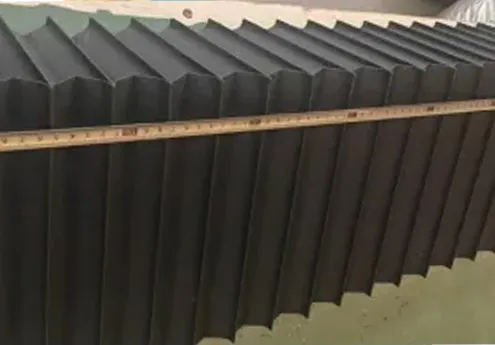

accordion bellows cover

Accordion bellows covers, a specialized type of protective covering, serve an important role in industrial and manufacturing environments. These covers safeguard machinery components, improve safety, and enhance machine longevity. When exploring the benefits and applications of accordion bellows covers, multiple facets of their importance come to the forefront.

Trustworthiness is a foundational aspect when considering the adoption of accordion bellows covers. Companies specializing in these products often uphold rigorous quality control standards, ensuring that every cover manufactured can withstand specific stress levels and environmental conditions. Furthermore, certifications from industry-standard bodies can assure clients of the product's reliability. Testimonials and case studies from established firms using bellows covers can bolster confidence, as these examples illustrate real-world durability and efficacy. The practical benefits offered by accordion bellows covers also have broader implications. Enhancing workplace safety is a primary concern for industries globally. By covering moving parts and shielding workers from potential hazards, these covers contribute significantly to a safer working environment. In addition, prevention of mechanical wear and tear results in extended machinery life cycles, contributing positively to sustainable manufacturing practices by reducing waste and conserving resources over time. In conclusion, accordion bellows covers represent an indispensable enhancement for industries reliant on precision and cleanliness in their operations. Their advantages are not limited to protecting equipment but extend to operational efficiency and workforce safety. When choosing a bellows cover, it is vital to consider factors such as material resilience, design conformity, and the reputation of the manufacturer. A well-chosen cover not only demonstrates careful investment into machine protection but also supports broader company goals of reliability, safety, and sustainability.

Trustworthiness is a foundational aspect when considering the adoption of accordion bellows covers. Companies specializing in these products often uphold rigorous quality control standards, ensuring that every cover manufactured can withstand specific stress levels and environmental conditions. Furthermore, certifications from industry-standard bodies can assure clients of the product's reliability. Testimonials and case studies from established firms using bellows covers can bolster confidence, as these examples illustrate real-world durability and efficacy. The practical benefits offered by accordion bellows covers also have broader implications. Enhancing workplace safety is a primary concern for industries globally. By covering moving parts and shielding workers from potential hazards, these covers contribute significantly to a safer working environment. In addition, prevention of mechanical wear and tear results in extended machinery life cycles, contributing positively to sustainable manufacturing practices by reducing waste and conserving resources over time. In conclusion, accordion bellows covers represent an indispensable enhancement for industries reliant on precision and cleanliness in their operations. Their advantages are not limited to protecting equipment but extend to operational efficiency and workforce safety. When choosing a bellows cover, it is vital to consider factors such as material resilience, design conformity, and the reputation of the manufacturer. A well-chosen cover not only demonstrates careful investment into machine protection but also supports broader company goals of reliability, safety, and sustainability.