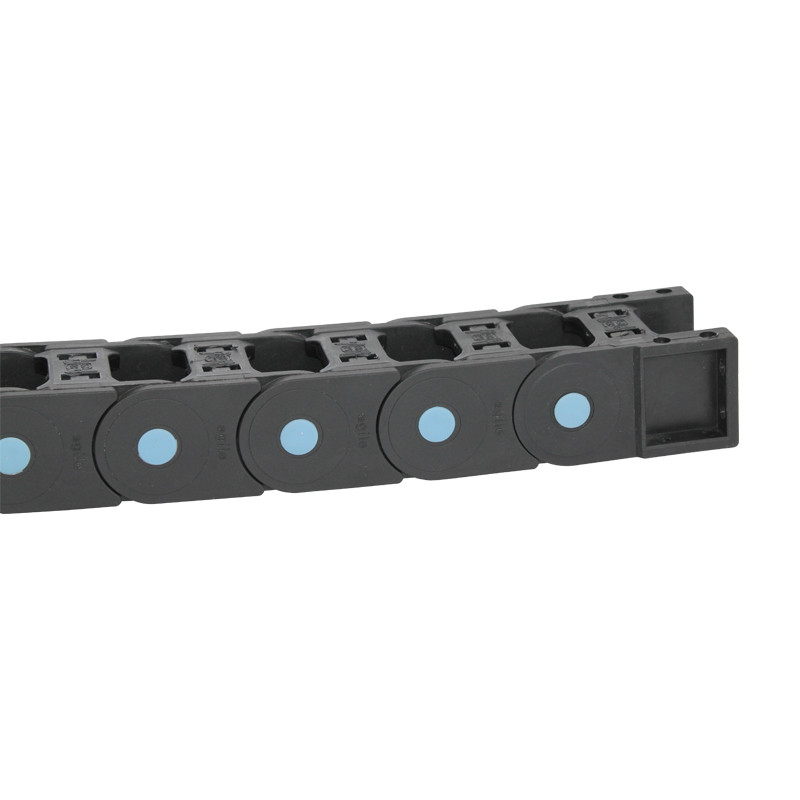

automotive wire loom tubing

Understanding Automotive Wire Loom Tubing A Key Component in Vehicle Wiring Systems

In the world of automotive engineering, every detail counts, and one often overlooked component is the wire loom tubing. Wire loom tubing plays a crucial role in the organization and protection of wiring setups within vehicles. As cars become increasingly sophisticated, with numerous electrical systems responsible for everything from engine management to entertainment features, the importance of effective wire management is more significant than ever.

What is Wire Loom Tubing?

Wire loom tubing is a protective cover designed to encase and organize electrical wires. It acts as a shield against abrasion, heat, moisture, and other environmental factors that can compromise the integrity of wiring. Typically made of durable materials like polyethylene, nylon, or PVC, wire loom tubing is essential for maintaining the health and longevity of vehicle electrical systems.

Why is it Important?

1. Protection from Damage The dynamic environment within a vehicle exposes wiring to various hazards. Wire loom tubing protects against abrasion caused by vibrations and movements of engine components, as well as moisture from engine coolant and rain. This protective barrier minimizes the risk of short circuits and electrical failures, ensuring the reliability of vital vehicle systems.

2. Organization In a modern vehicle, the number of wires can be overwhelming. Without proper organization, wires can become tangled, making troubleshooting and repairs more complicated and time-consuming. Wire loom tubing helps to group wires neatly, preventing them from intertwining, which is essential for efficient maintenance.

automotive wire loom tubing

3. Heat Resistance Motors and other components generate heat, which can be detrimental to wiring. Many wire loom tubings are designed to withstand high temperatures, ensuring that the wires inside remain unscathed. This heat resistance is particularly critical in areas close to the engine or other heat-producing elements.

4. Aesthetics Aside from functional benefits, wire loom tubing also contributes to the overall aesthetics of the vehicle’s wiring system. A neatly organized wiring loom can improve the visual appeal of engine bays and interior electronics, giving a clean and professional look.

Types of Wire Loom Tubing

Wire loom tubing comes in various sizes and colors to accommodate different wiring needs. Some of the common types include spiral wrap, split loom, and flexible tubing. Spiral wrap is often chosen for its easy application, as it can be wrapped around existing wires without needing to disconnect them. Split loom provides added flexibility, making it easier to install around bends and turns in wiring routes.

Conclusion

In conclusion, automotive wire loom tubing is an essential component of vehicle wiring systems, offering protection, organization, heat resistance, and a touch of aesthetic appeal. As automotive technology continues to evolve, the significance of effective wire management will only continue to grow, making quality wire loom tubing a critical consideration for manufacturers and enthusiasts alike. Whether you are designing a new vehicle or simply looking to improve your current setup, investing in high-quality wire loom tubing is a step in the right direction for ensuring the durability and functionality of your vehicle’s electrical systems.