10*15 mm MT small size mini nylon drag chain

In the intricate world of industrial machinery and automation, the role of a black plastic drag chain cable carrier is often underestimated. However, these remarkable components are the backbone of cable management systems across diverse sectors. This article delves into the effective utilization, technical prowess, authoritative applications, and trustworthy nature of black plastic drag chain cable carriers, providing an expansive understanding for industries looking to optimize their machinery efficiency and longevity.

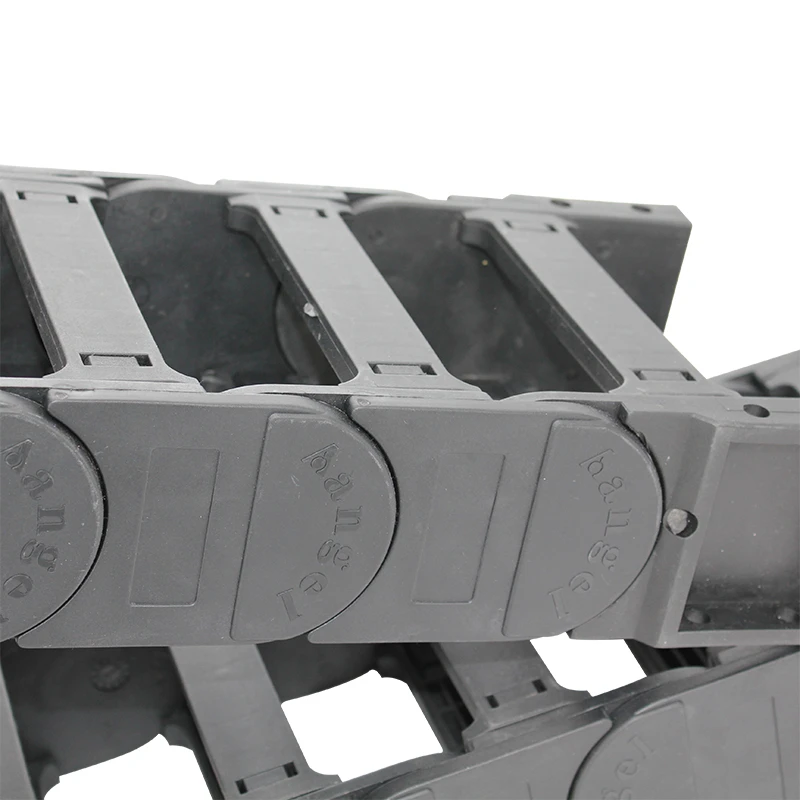

Trustworthiness is a paramount factor in selecting a cable carrier. Black plastic drag chain cable carriers hold a credible reputation due to their proven performance in the field. They offer reliability in numerous environments—ranging from chemical plants to robotic automation systems—demonstrating unmatched adaptability. Industries trust these carriers to ensure smooth operational flow and protect critical cable systems, thus reinforcing their value proposition. A user’s experience with black plastic drag chain cable carriers often starts with recognizing the need for a solution that mitigates cable-related issues in machinery. An effective cable management solution enhances operational efficiency, decreases downtime, and elevates overall productivity. Users report not only an immediate improvement in cable lifespan but also a decrease in maintenance interventions, which contributes to cost savings and increased efficiency—key performance indicators in any industrial setting. When black plastic drag chain cable carriers are implemented correctly, they exemplify exceptional durability and adaptability. They are integral in environments requiring high precision and reliability, including the automotive industry, aerospace sector, and electronics manufacturing. The decision to use these carriers often stems from their unparalleled performance and consistency, providing a significant ROI over extended operational periods. To sum up, the black plastic drag chain cable carrier is more than a mere component. It is an essential pillar supporting the infrastructure of modern automation and machinery. Its expert design, authoritative application standards, and proven trustworthy track record make it an indispensable tool for any industry reaping the benefits of cutting-edge technology in operational efficiency. Through continued innovation and unwavering reliability, these carriers remain a staple in maintaining the harmony between advanced technological demands and practical real-world applications.

Trustworthiness is a paramount factor in selecting a cable carrier. Black plastic drag chain cable carriers hold a credible reputation due to their proven performance in the field. They offer reliability in numerous environments—ranging from chemical plants to robotic automation systems—demonstrating unmatched adaptability. Industries trust these carriers to ensure smooth operational flow and protect critical cable systems, thus reinforcing their value proposition. A user’s experience with black plastic drag chain cable carriers often starts with recognizing the need for a solution that mitigates cable-related issues in machinery. An effective cable management solution enhances operational efficiency, decreases downtime, and elevates overall productivity. Users report not only an immediate improvement in cable lifespan but also a decrease in maintenance interventions, which contributes to cost savings and increased efficiency—key performance indicators in any industrial setting. When black plastic drag chain cable carriers are implemented correctly, they exemplify exceptional durability and adaptability. They are integral in environments requiring high precision and reliability, including the automotive industry, aerospace sector, and electronics manufacturing. The decision to use these carriers often stems from their unparalleled performance and consistency, providing a significant ROI over extended operational periods. To sum up, the black plastic drag chain cable carrier is more than a mere component. It is an essential pillar supporting the infrastructure of modern automation and machinery. Its expert design, authoritative application standards, and proven trustworthy track record make it an indispensable tool for any industry reaping the benefits of cutting-edge technology in operational efficiency. Through continued innovation and unwavering reliability, these carriers remain a staple in maintaining the harmony between advanced technological demands and practical real-world applications.