cable and hose carrier

Understanding Cable and Hose Carriers Essential Components in Modern Machinery

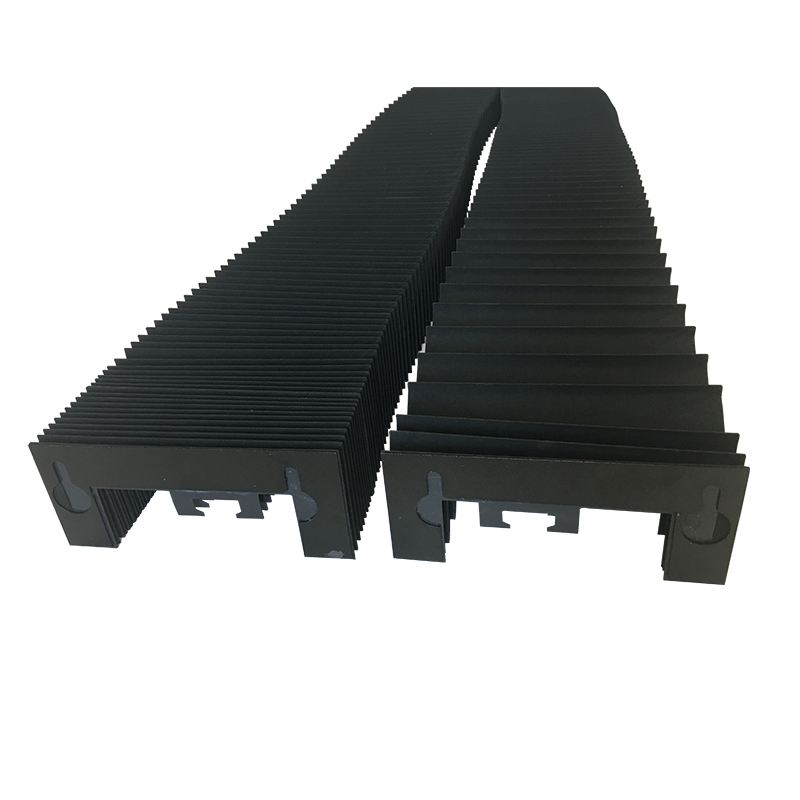

Cable and hose carriers, often referred to as cable track systems or drag chains, play a vital role in the functionality of modern machinery. These components are designed to guide, protect, and support flexible cables, wires, and hoses, ensuring they remain organized and free from damage during movement. As industries continue to adopt automation and advanced machinery, the importance of cable and hose carriers has become increasingly evident.

The primary function of a cable and hose carrier is to manage the movement of cables and hoses in applications involving motion. For instance, in robotic arms or CNC machines, these carriers allow for the seamless movement of electrical and pneumatic components while preventing tangles and wear. Without these systems, cables and hoses would be vulnerable to friction and abrasion, leading to premature failure and costly downtime.

Cable and hose carriers come in various shapes and sizes, designed for different applications. They can be made from various materials, including high-density polyethylene, steel, or aluminum, each chosen for its specific properties such as flexibility, strength, and resistance to environmental factors. Customization is also a significant aspect of these systems; manufacturers often produce tailored solutions to fit unique machinery specifications.

cable and hose carrier

One of the key benefits of these carriers is their ability to reduce wear and tear on cables and hoses. They provide a protective enclosure, shielding sensitive components from external conditions such as dust, debris, and moisture. Moreover, the organized routing provided by these carriers not only enhances the aesthetic aspect of machinery but also contributes to operational efficiency. Workers can easily identify and troubleshoot issues, leading to faster maintenance and reduced operational interruptions.

In addition to their protective qualities, cable and hose carriers are designed to accommodate various movement types. Whether it’s linear movement, rotary motion, or a combination of both, these systems can adapt to ensure that the cables and hoses are not subjected to excessive stress. Many models also feature modular designs, allowing for easy installation and modifications to existing systems.

Advancements in technology have further enhanced the performance of cable and hose carriers. Innovations such as low-friction materials and energy-efficient designs are becoming standard, providing smoother operation and less energy consumption. Furthermore, manufacturers are increasingly focusing on developing eco-friendly materials to cater to the growing demand for sustainable solutions in industry.

In conclusion, cable and hose carriers are indispensable components in the realm of machinery and automation. By ensuring the safe and effective routing of cables and hoses, these systems contribute to increased productivity, reduced maintenance costs, and enhanced operational efficiency. As industries continue to evolve and automate, the role of cable and hose carriers will undoubtedly expand, making them a fundamental element in modern engineering design.