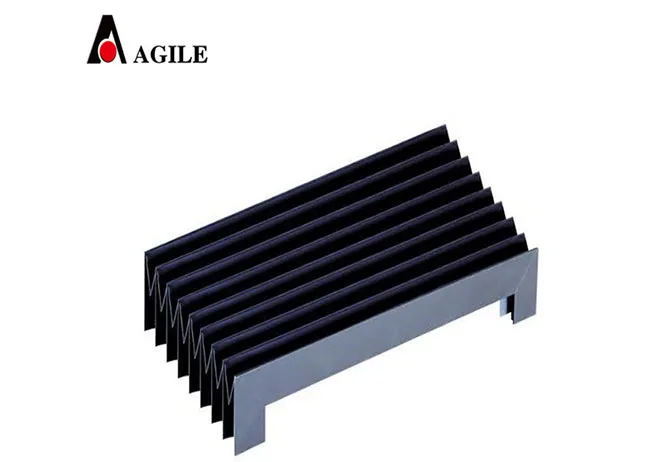

cable and hose carrier

Cable and hose carriers, often referred to as energy chains or drag chains, are critical components in various industries, ensuring aligned and protected pathways for cables and hoses. Their significance extends to industrial automation, robotics, and machinery where precise motion and reliability are paramount. Understanding their importance not only enlightens their functionality but assures the judicious selection and application in real-world scenarios.

Authorities in mechanical engineering and industrial automation often reference successful case studies of cable and hose carriers that have triumphed in mitigating downtimes and costs. Notably, in prominent logistics operations, where sorting and packaging require perpetual artificial intelligence-driven systems, the employment of high-quality carriers has halved maintenance efforts, while bolstering predictability in operations. This realignment of reliability further strengthens the stronghold of cable carriers as indispensable systems. For discerning engineers and technicians in pursuit of expertise, trust in cable and hose carrier brands that invest heavily in research and development guarantees security. These products backed by extensive testing and compliance with international safety standards create invaluable trust within markets. Engaging with brands that possess a cogent history of innovation in cable carriers instills confidence and reassures satisfactory alignment with specific industry requirements. Furthermore, the trustworthy aspect of cable and hose carriers is emboldened through a commitment to ongoing education and professional development. Manufacturers offering training and certification underscore the importance of correct installation and maintenance, promoting best practices that resonate with technical teams worldwide. This confluence of knowledge transfer and product integrity underlines a mutual dependency on high-caliber carriers to drive inventive solutions across diversified industrial landscapes. In conclusion, the vitality of cable and hose carriers transcends basic utility. They embody precision, express expert validation, and are emblematic of trust in engineering design. As industries continue to forge pathways to increased automation and specified functionalities, the nuanced selection and application of these carriers remain instrumental in fostering relentless productivity and innovative breakthroughs. Emulating best practices in carrier selection not only guards against operational pitfalls but etches a cultural landscape where reliable, focused engineering solutions thrive sustainably.

Authorities in mechanical engineering and industrial automation often reference successful case studies of cable and hose carriers that have triumphed in mitigating downtimes and costs. Notably, in prominent logistics operations, where sorting and packaging require perpetual artificial intelligence-driven systems, the employment of high-quality carriers has halved maintenance efforts, while bolstering predictability in operations. This realignment of reliability further strengthens the stronghold of cable carriers as indispensable systems. For discerning engineers and technicians in pursuit of expertise, trust in cable and hose carrier brands that invest heavily in research and development guarantees security. These products backed by extensive testing and compliance with international safety standards create invaluable trust within markets. Engaging with brands that possess a cogent history of innovation in cable carriers instills confidence and reassures satisfactory alignment with specific industry requirements. Furthermore, the trustworthy aspect of cable and hose carriers is emboldened through a commitment to ongoing education and professional development. Manufacturers offering training and certification underscore the importance of correct installation and maintenance, promoting best practices that resonate with technical teams worldwide. This confluence of knowledge transfer and product integrity underlines a mutual dependency on high-caliber carriers to drive inventive solutions across diversified industrial landscapes. In conclusion, the vitality of cable and hose carriers transcends basic utility. They embody precision, express expert validation, and are emblematic of trust in engineering design. As industries continue to forge pathways to increased automation and specified functionalities, the nuanced selection and application of these carriers remain instrumental in fostering relentless productivity and innovative breakthroughs. Emulating best practices in carrier selection not only guards against operational pitfalls but etches a cultural landscape where reliable, focused engineering solutions thrive sustainably.