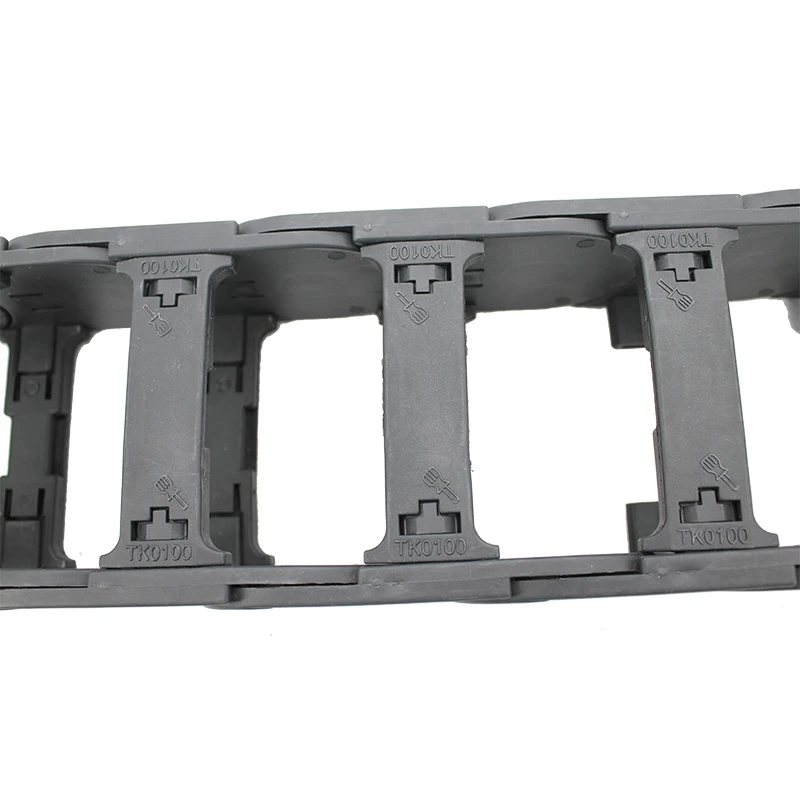

flexible cable carrier

Cable and hose carrier systems have revolutionized how industries manage their automation and mechanical tasks, acting as pivotal components that enhance both efficiency and operational longevity. Known for their adaptability, these systems are indispensable in sectors ranging from automotive production lines to complex aerospace projects.

Trustworthiness of cable and hose carrier systems is also critical. Manufacturers need to ensure compliance with international standards such as ISO and RoHS. Certification not only guarantees quality but also reassures end-users of the system’s longevity and safety. Regular audits and stress testing are common practices among leading manufacturers to maintain this trust. Testimonials and case studies from industries using top-tier cable and hose carrier systems often reveal insights into their value proposition. An automotive production plant, for instance, saw a 20% increase in efficiency after upgrading to a new composite carrier system, which reduced maintenance times and costs significantly. This experiential evidence underscores the tangible benefits of investing in high-quality systems. Furthermore, advancements in technology have led to smart cable and hose carrier systems. These innovative products incorporate sensors to monitor the health of the system, predicting failures before they occur. This proactive approach is transforming traditional maintenance strategies into more predictive and less intrusive practices. In conclusion, the role of cable and hose carrier systems in today’s industrial landscape is more critical than ever. Selections based on real-world experience, combined with technical expertise, and guided by compliant and authoritative manufacturing practices, ensure that they not only meet but exceed operational demands. Trust in these systems is built over time through stringent testing, continuous innovation, and proven performance. As industries evolve, so too will these essential components, driving forward the efficiency and efficacy of machines worldwide.

Trustworthiness of cable and hose carrier systems is also critical. Manufacturers need to ensure compliance with international standards such as ISO and RoHS. Certification not only guarantees quality but also reassures end-users of the system’s longevity and safety. Regular audits and stress testing are common practices among leading manufacturers to maintain this trust. Testimonials and case studies from industries using top-tier cable and hose carrier systems often reveal insights into their value proposition. An automotive production plant, for instance, saw a 20% increase in efficiency after upgrading to a new composite carrier system, which reduced maintenance times and costs significantly. This experiential evidence underscores the tangible benefits of investing in high-quality systems. Furthermore, advancements in technology have led to smart cable and hose carrier systems. These innovative products incorporate sensors to monitor the health of the system, predicting failures before they occur. This proactive approach is transforming traditional maintenance strategies into more predictive and less intrusive practices. In conclusion, the role of cable and hose carrier systems in today’s industrial landscape is more critical than ever. Selections based on real-world experience, combined with technical expertise, and guided by compliant and authoritative manufacturing practices, ensure that they not only meet but exceed operational demands. Trust in these systems is built over time through stringent testing, continuous innovation, and proven performance. As industries evolve, so too will these essential components, driving forward the efficiency and efficacy of machines worldwide.