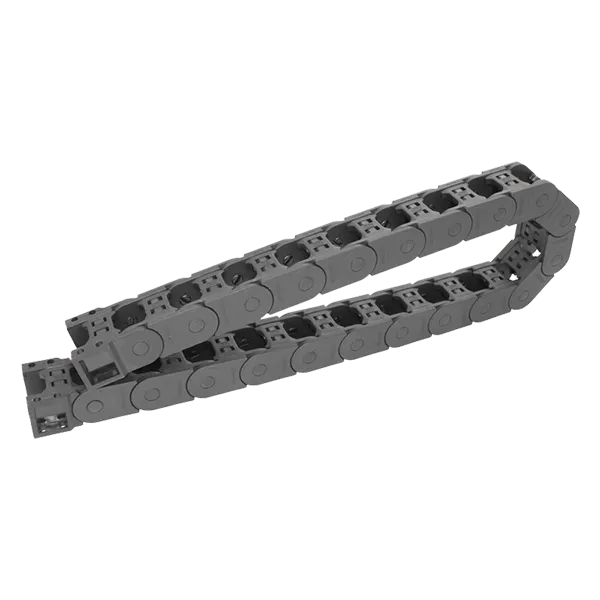

60*150 mm MT open type nylon flexible both side openable cable chain

Cable carriers are an essential component for efficient energy management in various industrial applications, ensuring that power and data reach where they are needed without interruption. Drawing from years of experience in industrial solutions, I have seen firsthand the transformative role of cable carriers in enhancing productivity and reliability across many sectors.

These specialized devices, often crafted with high-grade plastic or reinforced steel, provide the necessary structural support to guide and protect cables during operation. In assembly lines, robotic arms, and other automated machinery, the constant movement places immense stress on cables. Without the protection offered by a robust cable carrier, these cables risk tangling or sustaining damage, leading to costly downtime.

From an expertise standpoint, understanding the nuances of cable carriers is imperative. They come in various types, including open and closed carriers, each suited for specific environments. Open carriers, for example, are well-suited for areas requiring minimal protection from dust, whereas closed carriers are optimal for environments where foreign particulates are a concern. Selecting the right type involves a thorough analysis of the operational environment, movement patterns, and the specific needs of the machinery in use.

The authoritativeness of cable carriers in the industrial domain cannot be overstated. They have become a standard in industries ranging from automotive manufacturing to semiconductor production, where precision and uninterrupted processes are critical. The longevity and performance of a machine are heavily contingent upon the reliability of its cable management system. Manufacturers often recommend specific cable carrier systems to guarantee optimal performance, and compliance with these recommendations can significantly impact a machine's lifespan and efficacy.

cable carrier

In terms of trustworthiness, reputable cable carrier manufacturers subject their products to rigorous testing, ensuring they meet industry standards such as ISO and UL. These standards serve as a testament to a product's quality and reliability, providing confidence to businesses investing in these systems. It is not uncommon for businesses to seek testimonials and case studies from existing users when selecting a cable carrier system, as these real-world applications offer invaluable insights into product performance over time.

Investing in high-quality cable carriers is an investment in operational excellence. The initial expenditure is typically offset by the subsequent reduction in maintenance costs and downtime. Moreover, as industries continue to innovate, the evolution of cable carriers keeps pace, incorporating advanced materials and designs to accommodate higher speeds and more complex machinery.

In conclusion, cable carriers play a pivotal role in modern industrial applications, providing not just cable protection but enhancing operational efficiency and reliability. For businesses aiming to optimize their production lines, paying close attention to the selection and maintenance of cable carriers is crucial. This commitment to quality and expertise ensures that operations remain smooth, efficient, and cost-effective, setting a foundation for long-term success.