Top Cable Carrier Solutions for Reliable Performance

The world of automation and industrial technology constantly evolves, pushing the boundaries of efficiency and innovation. One of the unsung heroes in this domain is the cable carrier. Despite its often overlooked role, it is crucial for protecting and guiding cables in dynamic environments. Drawing from over a decade of experience within the industrial solutions sector, I have observed how essential cable carriers are to the seamless operation of various applications.

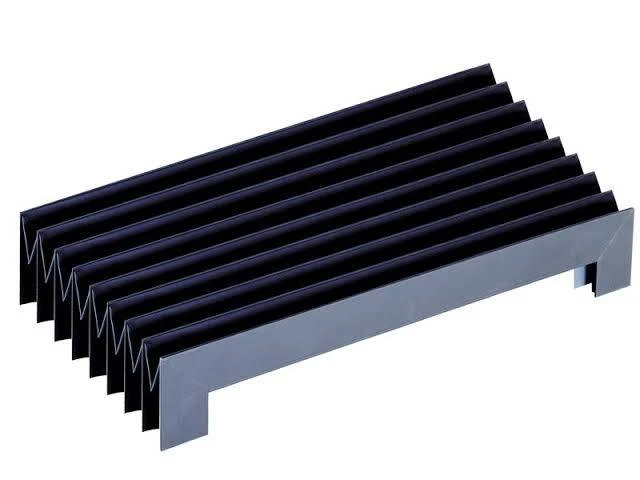

Cable carriers are pivotal in ensuring the longevity and reliability of cables used in fields ranging from robotics to industrial manufacturing. These devices act as protective conduits, designed to guide and protect electrical cables, hydraulic or pneumatic hoses attached to automated machinery. By preventing tangling, twisting, and damage, they help maintain uninterrupted power and control signal transmission, which is paramount for any automated process.

From an expertise standpoint, the choice of a cable carrier should align with the specific dynamics of the application. Factors such as travel length, required stability, installation space, and environmental conditions—like exposure to chemicals or extreme temperatures—can significantly influence the appropriate selection. Understanding the material composition, whether it be steel, plastic, or hybrid variations, is also essential. Steel cable carriers, for example, are ideal for heavy-duty applications where maximum protection is necessary, whereas plastic carriers might be preferred for lighter tasks involving rapid movement and flexibility.

Moreover, the authority in cable carrier technology is often represented by leading manufacturers who continue to innovate in design and functionality. These companies, through years of R&D, have developed products that not only meet but exceed industry standards. Consulting with such manufacturers or their authorized distributors provides insights into the latest advancements and ensures that decisions are supported by authoritative guidance.

Trust in cable carrier systems is built through rigorous testing and compliance with international safety standards. Engaging with suppliers who prioritize quality assurance processes, such as ISO certification, provides a level of confidence in the product's performance and longevity. It's also advisable to seek suppliers who offer ergonomic installation designs, technical support, and warranty policies which collectively guarantee trustworthy service and product reliability.

In sum, the strategic integration of cable carriers in industrial applications reflects a commitment to operational excellence. They are indispensable components that enhance the durability, safety, and efficiency of automated systems. Professionals who are seeking to optimize their systems must choose cable carriers that are tailored to their specific needs, sourced from reputable manufacturers, and supported by a robust technical service. This approach ensures that the industrial landscape remains adaptive, secure, and ready for future technological challenges.