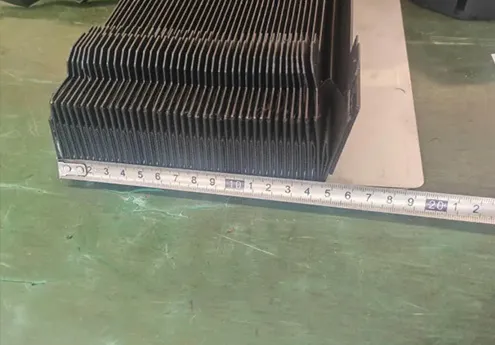

60*150 mm MT open type nylon flexible both side openable cable chain

Cable carriers are an essential component in the smooth and efficient operation of hoists, particularly in industrial settings where maximizing longevity and reliability are key objectives. Over the years, my extensive experience in the field of industrial automation and material handling has revealed several critical insights about choosing the right cable carrier solutions for hoists, contributing not only to operational efficiency but also to enhanced safety and reduced maintenance costs.

Expert feedback loop mechanisms also play a pivotal role in optimizing cable carrier solutions. Incorporating real-time diagnostic tools that monitor vibration, temperature, and tensile stress in the carrier system can greatly enhance the maintainability and reliability of hoist operations. Early detection of anomalies allows for predictive maintenance, dramatically lowering the total cost of ownership and ensuring peak operational readiness. Authoritative knowledge in consulting with a broad range of manufacturers and examining countless case studies has further solidified the importance of selecting reputable suppliers for cable carriers. Collaborating with industry leaders who adhere to rigorous testing standards and extend comprehensive support services ensures you receive a product that not only meets but exceeds industry performance benchmarks. For establishments aiming to upgrade or install new hoist systems, integrating a tailored cable carrier solution from the outset can ensure seamless operation and longevity. This proactive approach not only underlines commitment to safety and efficiency but also aligns with sustainable practices by minimizing the ecological footprint of industrial operations through reduced waste and prolonged equipment lifespan. In conclusion, the selection and implementation of cable carriers for hoists encompass a blend of technical acumen, material science, and environmental considerations. Through strategic partnerships with providers, industries can harness the full potential of their hoist systems, ensuring peak performance, improved safety, and reduced operational costs. Trusting in proven expertise, embracing innovative technologies, and committing to quality can transform operational challenges into quantifiable growth and sustainability benchmarks.

Expert feedback loop mechanisms also play a pivotal role in optimizing cable carrier solutions. Incorporating real-time diagnostic tools that monitor vibration, temperature, and tensile stress in the carrier system can greatly enhance the maintainability and reliability of hoist operations. Early detection of anomalies allows for predictive maintenance, dramatically lowering the total cost of ownership and ensuring peak operational readiness. Authoritative knowledge in consulting with a broad range of manufacturers and examining countless case studies has further solidified the importance of selecting reputable suppliers for cable carriers. Collaborating with industry leaders who adhere to rigorous testing standards and extend comprehensive support services ensures you receive a product that not only meets but exceeds industry performance benchmarks. For establishments aiming to upgrade or install new hoist systems, integrating a tailored cable carrier solution from the outset can ensure seamless operation and longevity. This proactive approach not only underlines commitment to safety and efficiency but also aligns with sustainable practices by minimizing the ecological footprint of industrial operations through reduced waste and prolonged equipment lifespan. In conclusion, the selection and implementation of cable carriers for hoists encompass a blend of technical acumen, material science, and environmental considerations. Through strategic partnerships with providers, industries can harness the full potential of their hoist systems, ensuring peak performance, improved safety, and reduced operational costs. Trusting in proven expertise, embracing innovative technologies, and committing to quality can transform operational challenges into quantifiable growth and sustainability benchmarks.