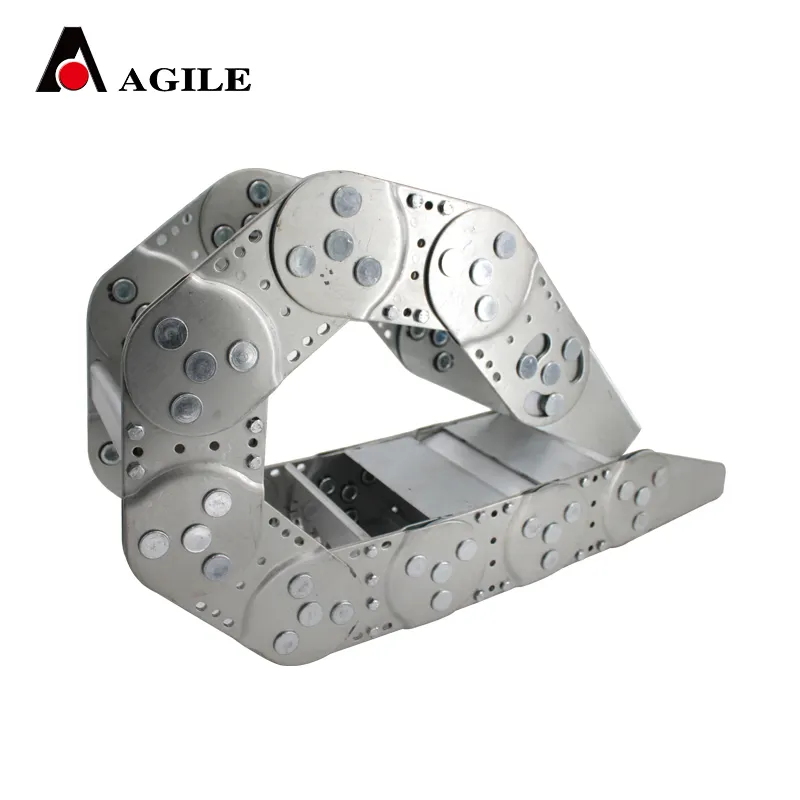

flexible cable carrier

Selecting the right cable carrier manufacturer is essential for industries reliant on machinery and automation. Cable carriers, also known as drag chains, play a pivotal role in ensuring that the delicate cables of machinery move seamlessly without wear and tear. Their primary function is to guide and protect flexible cables and hoses on automated equipment that moves. In this article, we will explore the facets of cable carrier manufacturers, emphasizing experience, expertise, authoritativeness, and trustworthiness, helping you make an informed decision for your specific needs.

Trustworthiness is the foundation of any client-manufacturer relationship. Trustworthy manufacturers prioritize customer satisfaction; they offer not only premium products but also outstanding post-purchase services. This includes comprehensive warranties, accessible customer support, and a straightforward, transparent purchasing process. Many respected cable carrier manufacturers are ISO certified, which reassures clients that their products meet international standards for safety, quality, and efficiency. They understand the critical nature of downtime in industrial settings and hence maintain robust supply chains to ensure swift delivery and minimal interruptions. One of the deciding factors in choosing a cable carrier manufacturer is the range of products they offer. Leading manufacturers provide a comprehensive product lineup featuring plastic and metal cable carriers, each designed to cater to different environmental conditions such as heat, chemical exposure, and heavy mechanical stresses. Their offerings often include modular designs that allow for easy assembly and disassembly, facilitating maintenance and reducing downtime. The versatility and adaptability of their products reflect their understanding of industry needs. Innovative manufacturers are also keenly aware of environmental and economic concerns. Many have adopted sustainable practices, using recyclable materials and energy-efficient manufacturing processes. This commitment not only helps reduce the environmental footprint but also aligns them with clients who are equally committed to sustainability goals. In conclusion, the choice of a cable carrier manufacturer should be guided by experience, expertise, authoritativeness, and trustworthiness. A manufacturer who excels in these areas can provide reliable, efficient, and innovative products that drive productivity while protecting valuable machinery components. Extensive research, a keen understanding of specific needs, and a consultation with knowledgeable industry experts will aid in making the most informed decision. As industries evolve, partnering with a forward-thinking cable carrier manufacturer can be a significant advantage, ensuring seamless operations and sustained success.

Trustworthiness is the foundation of any client-manufacturer relationship. Trustworthy manufacturers prioritize customer satisfaction; they offer not only premium products but also outstanding post-purchase services. This includes comprehensive warranties, accessible customer support, and a straightforward, transparent purchasing process. Many respected cable carrier manufacturers are ISO certified, which reassures clients that their products meet international standards for safety, quality, and efficiency. They understand the critical nature of downtime in industrial settings and hence maintain robust supply chains to ensure swift delivery and minimal interruptions. One of the deciding factors in choosing a cable carrier manufacturer is the range of products they offer. Leading manufacturers provide a comprehensive product lineup featuring plastic and metal cable carriers, each designed to cater to different environmental conditions such as heat, chemical exposure, and heavy mechanical stresses. Their offerings often include modular designs that allow for easy assembly and disassembly, facilitating maintenance and reducing downtime. The versatility and adaptability of their products reflect their understanding of industry needs. Innovative manufacturers are also keenly aware of environmental and economic concerns. Many have adopted sustainable practices, using recyclable materials and energy-efficient manufacturing processes. This commitment not only helps reduce the environmental footprint but also aligns them with clients who are equally committed to sustainability goals. In conclusion, the choice of a cable carrier manufacturer should be guided by experience, expertise, authoritativeness, and trustworthiness. A manufacturer who excels in these areas can provide reliable, efficient, and innovative products that drive productivity while protecting valuable machinery components. Extensive research, a keen understanding of specific needs, and a consultation with knowledgeable industry experts will aid in making the most informed decision. As industries evolve, partnering with a forward-thinking cable carrier manufacturer can be a significant advantage, ensuring seamless operations and sustained success.