cable carrier system

The Cable Carrier System An Essential Component of Modern Engineering

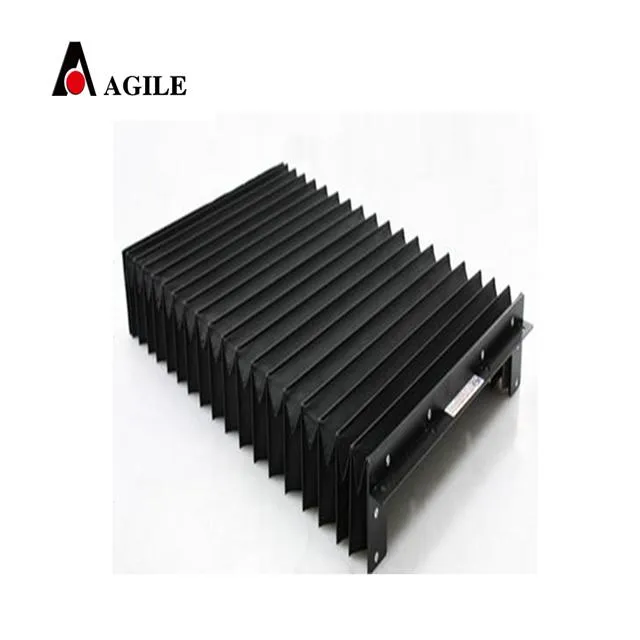

In today's fast-paced industrial environment, the efficient management of cables is vital for maintaining productivity and safety. Among the solutions designed to address these challenges is the cable carrier system, often referred to as cable tracks or drag chains. These systems play a crucial role in various applications, from manufacturing to robotics, ensuring that electrical and data cables are organized, protected, and able to move freely with machinery.

A cable carrier system essentially consists of a series of links that form a chain-like structure, which is mounted to a fixed point and moves as machinery operates

. This design allows cables and hoses to be guided along a predetermined path, minimizing wear and tear while preventing tangling and pinching. The fundamental purpose of these carriers is to provide a safe and reliable means of cable management in dynamic environments, where movement and flexibility are required.One of the key advantages of a cable carrier system is its ability to streamline operations. In environments such as manufacturing plants, where machines frequently move and change positions, the ability to have cables neatly guided prevents potential downtime caused by cable damage. This is particularly important in automated systems, where interruptions can lead to costly delays. By incorporating a cable carrier system, companies can enhance the longevity of their equipment and maintain a higher level of productivity.

cable carrier system

Moreover, cable carriers are designed with durability in mind. They are commonly made from materials such as nylon, steel, or plastic, which can resist harsh environmental conditions, including extreme temperatures, moisture, and chemical exposure. This resilience makes them suitable for a wide range of applications, including CNC machines, robots, and even large construction equipment. The design can also be customized to fit specific needs, allowing for various widths, heights, and types of links to accommodate different cable sizes and weights.

In addition to physical protection, cable carriers also contribute to the safety of operational environments. By keeping cables organized and securely in place, they help minimize the risk of tripping hazards and electrical hazards, which is especially important in busy industrial settings where multiple employees and machinery co-exist. Furthermore, the use of cable carriers can streamline maintenance processes, allowing for easy access to cables when repairs or replacements are needed.

The future of cable carrier systems also looks promising with advancements in technology. Innovations such as flexible cable carriers that can bend in multiple dimensions or those integrated with monitoring systems for predictive maintenance are beginning to gain traction. These advancements not only improve functionality but also enhance operational efficiency, making cable carriers an even more integral part of modern engineering.

In conclusion, the cable carrier system is a vital component in the landscape of industrial engineering. Its ability to ensure the organization, protection, and management of cables enhances productivity and safety in various settings. As technology continues to evolve, we can expect these systems to become even more sophisticated, further solidifying their importance in the fields of manufacturing, automation, and beyond.