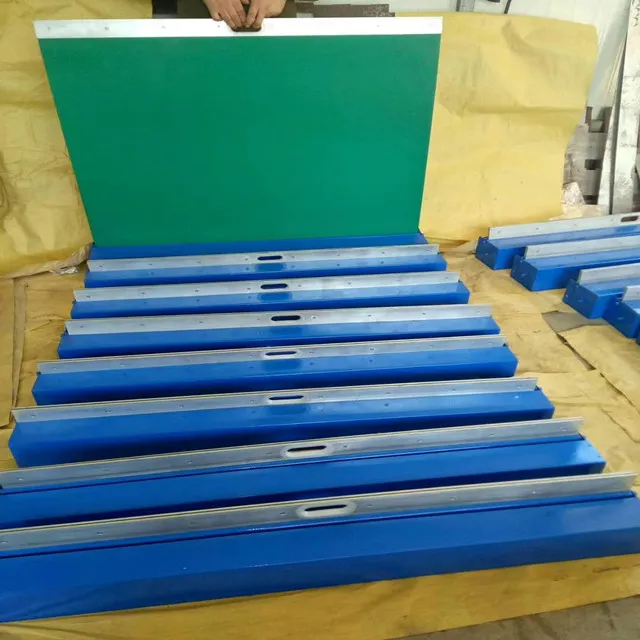

cable carrier track

Cable carrier tracks, often simply referred to as cable tracks or drag chains, play an indispensable role in numerous industries by providing a protective guide for moving cables and hoses. These components, while seemingly simple, have a profound impact on the functionality and efficiency of industrial equipment. Their importance underscores the necessity of keen understanding and careful selection for specific applications.

Real-world experience with cable carrier tracks further underscores their value. In industrial automation systems, where precision and timing are critical, failing cable tracks can result in costly downtime. Companies sharing documented experiences of improved machine uptime and reduced maintenance costs after implementing high-quality tracks provide valuable insights into their effectiveness. These testimonials, based on long-term performance data, reinforce the credibility of the chosen solutions and exemplify their impact through real-world application. Among the key challenges faced by maintenance teams is ensuring that the cable carrier track system remains unaffected by debris accumulation or obstructions. Regular inspection and maintenance, guided by established best practices, are critical. These include checks for wear and tear, proper alignment, and tension adjustments, ensuring that the system performs as designed. In conclusion, the strategic use of cable carrier tracks is not merely an accessory choice but a critical investment in the maintenance of operational integrity and efficiency. Their role in safeguarding cables, enhancing production line reliability, and reducing operational risks is unparalleled. Organizations armed with authoritative knowledge and firsthand experience in utilizing these tracks can anticipate significant improvements in their operational outcomes. Understanding the nuances of their application and maintenance further ensures the longevity and reliability of these indispensable components in any mechanical system.

Real-world experience with cable carrier tracks further underscores their value. In industrial automation systems, where precision and timing are critical, failing cable tracks can result in costly downtime. Companies sharing documented experiences of improved machine uptime and reduced maintenance costs after implementing high-quality tracks provide valuable insights into their effectiveness. These testimonials, based on long-term performance data, reinforce the credibility of the chosen solutions and exemplify their impact through real-world application. Among the key challenges faced by maintenance teams is ensuring that the cable carrier track system remains unaffected by debris accumulation or obstructions. Regular inspection and maintenance, guided by established best practices, are critical. These include checks for wear and tear, proper alignment, and tension adjustments, ensuring that the system performs as designed. In conclusion, the strategic use of cable carrier tracks is not merely an accessory choice but a critical investment in the maintenance of operational integrity and efficiency. Their role in safeguarding cables, enhancing production line reliability, and reducing operational risks is unparalleled. Organizations armed with authoritative knowledge and firsthand experience in utilizing these tracks can anticipate significant improvements in their operational outcomes. Understanding the nuances of their application and maintenance further ensures the longevity and reliability of these indispensable components in any mechanical system.