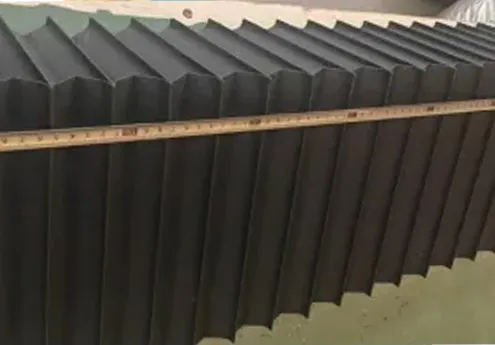

10*15 mm MT small size mini nylon drag chain

Cable cat tracks, often referred to as cable carriers or drag chains, play a pivotal role in numerous industries, revolutionizing how cables and hoses are managed in dynamic applications. Their introduction has significantly enhanced efficiency and safety, positioning them as indispensable tools in sectors ranging from manufacturing to robotics to medical equipment. Understanding the nuances of cable cat tracks isn't just about recognizing their function but appreciating the precision engineering and foresight that goes into designing these critical components.

In robotics, where precision is non-negotiable, cable cat tracks ensure that robotic arms function optimally without the hindrance of tangled or stiff cables. The predictability and reliability offered by these tracks are paramount, providing trustworthiness and confidence to operators and engineers alike. With the integration of smart technology, some modern cable cat tracks now offer monitoring systems that provide real-time data on wear and performance, further solidifying their role as trustworthy components in automated systems. Trustworthiness is further reinforced through rigorous testing and quality assurance processes. Each cable cat track system undergoes extensive testing to simulate various operational stresses and environmental conditions. Manufacturers conduct tests to measure the durability of materials, the effectiveness of strain relief features, and the integrity of connections under repeated motion. These assurances are crucial for industries where reliability directly impacts safety and productivity. Users of cable cat tracks consistently report their effectiveness in improving machine uptime and reducing maintenance costs. Case studies highlight instances where companies have transitioned from traditional cable management systems to cable cat tracks, witnessing significant improvements in efficiency and a marked reduction in cable-related failures. Such real-world experiences add credibility to the claims made by manufacturers, offering potential customers tangible evidence of the benefits these systems provide. In summation, cable cat tracks are more than just accessories; they are vital components engineered to enhance the performance and reliability of complex systems. The fusion of experience, expertise, authority, and trust in their design and application illustrates why they remain unparalleled in their ability to solve cable management challenges in dynamic settings. For companies looking to optimize operational efficiency while safeguarding critical systems, investing in high-quality cable cat tracks is an informed choice backed by industry expertise and proven effectiveness.

In robotics, where precision is non-negotiable, cable cat tracks ensure that robotic arms function optimally without the hindrance of tangled or stiff cables. The predictability and reliability offered by these tracks are paramount, providing trustworthiness and confidence to operators and engineers alike. With the integration of smart technology, some modern cable cat tracks now offer monitoring systems that provide real-time data on wear and performance, further solidifying their role as trustworthy components in automated systems. Trustworthiness is further reinforced through rigorous testing and quality assurance processes. Each cable cat track system undergoes extensive testing to simulate various operational stresses and environmental conditions. Manufacturers conduct tests to measure the durability of materials, the effectiveness of strain relief features, and the integrity of connections under repeated motion. These assurances are crucial for industries where reliability directly impacts safety and productivity. Users of cable cat tracks consistently report their effectiveness in improving machine uptime and reducing maintenance costs. Case studies highlight instances where companies have transitioned from traditional cable management systems to cable cat tracks, witnessing significant improvements in efficiency and a marked reduction in cable-related failures. Such real-world experiences add credibility to the claims made by manufacturers, offering potential customers tangible evidence of the benefits these systems provide. In summation, cable cat tracks are more than just accessories; they are vital components engineered to enhance the performance and reliability of complex systems. The fusion of experience, expertise, authority, and trust in their design and application illustrates why they remain unparalleled in their ability to solve cable management challenges in dynamic settings. For companies looking to optimize operational efficiency while safeguarding critical systems, investing in high-quality cable cat tracks is an informed choice backed by industry expertise and proven effectiveness.