10*15 mm MT small size mini nylon drag chain

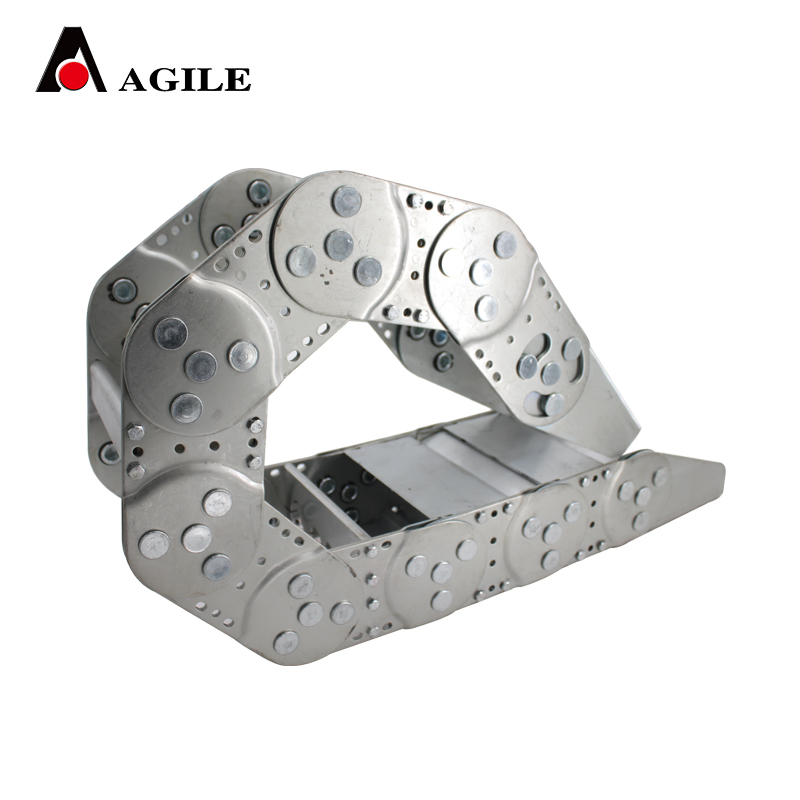

Cable chain tracks, often dubbed the spine of industrial machinery, play an indispensable role in modern manufacturing and automation. Their silent function behind the scenes ensures the organized and efficient movement of cables and hoses on various types of equipment. Having traversed multiple factory floors and deep-dived into the intricacies of their application, I can assert the pivotal importance of these underrated components.

Trustworthiness in cable chain tracks extends beyond their immediate functionality. Reputable manufacturers provide extensive testing data and guarantee longevity backed by compelling warranties. This transparency is crucial, reassuring clients of the product’s integrity and capability. For example, a reliable manufacturer may present data from accelerated lifecycle tests that simulate years of use in mere weeks. Having observed such presentations, it's clear that not all tracks are built equal, and investing in those with proven endurance pays off in the long run. A hands-on demonstration often eclipses theoretical knowledge. In facilities where machinery undergoes complex movements, witnessing a cable chain track in action provides unmatched insight. As an observer in such environments, the consistent movement without snags, tangles, or undue tension is an impressive sight. Such seamless operation is crucial for high-output establishments where time is money, and unexpected halts equate to potential revenue losses. In conclusion, the cable chain track is an essential yet often underestimated component central to the smooth operation of automated systems. With proper selection, implementation, and maintenance, these tracks can significantly enhance productivity and reduce overheads. Emphasizing reliability, professional knowledge, and manufacturer trustworthiness should guide stakeholders in their purchasing decisions, knowing that the right cable chain track is an investment in consistent operational success.

Trustworthiness in cable chain tracks extends beyond their immediate functionality. Reputable manufacturers provide extensive testing data and guarantee longevity backed by compelling warranties. This transparency is crucial, reassuring clients of the product’s integrity and capability. For example, a reliable manufacturer may present data from accelerated lifecycle tests that simulate years of use in mere weeks. Having observed such presentations, it's clear that not all tracks are built equal, and investing in those with proven endurance pays off in the long run. A hands-on demonstration often eclipses theoretical knowledge. In facilities where machinery undergoes complex movements, witnessing a cable chain track in action provides unmatched insight. As an observer in such environments, the consistent movement without snags, tangles, or undue tension is an impressive sight. Such seamless operation is crucial for high-output establishments where time is money, and unexpected halts equate to potential revenue losses. In conclusion, the cable chain track is an essential yet often underestimated component central to the smooth operation of automated systems. With proper selection, implementation, and maintenance, these tracks can significantly enhance productivity and reduce overheads. Emphasizing reliability, professional knowledge, and manufacturer trustworthiness should guide stakeholders in their purchasing decisions, knowing that the right cable chain track is an investment in consistent operational success.