cat track electrical

Understanding Cat Track Electrical Systems A Comprehensive Overview

The evolution of electrical systems in heavy machinery, particularly in Caterpillar (CAT) tracks, has revolutionized the way industries operate. CAT track electrical systems are integral to the functionality of their heavy equipment, such as excavators, bulldozers, and other earth-moving machines. These systems support various operations, including movement, navigation, and efficiency, enhancing productivity and reducing environmental impact.

What is CAT Track Electrical?

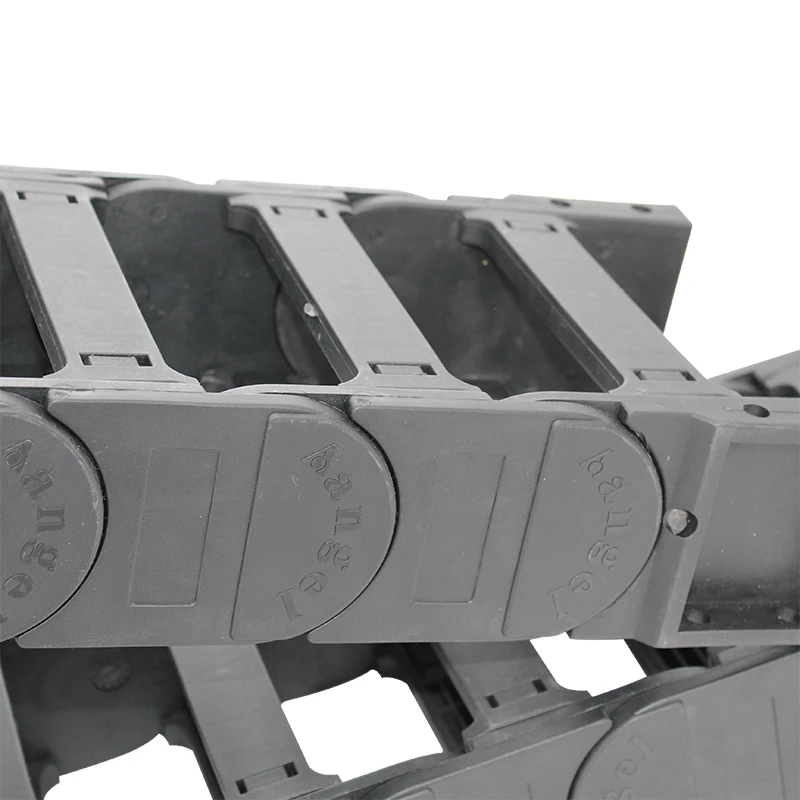

CAT track electrical systems encompass all electrical components related to the operation of Caterpillar equipment. This includes wiring, connectors, sensors, control units, and the integration of advanced technologies such as telematics and automation. These systems are designed to optimize performance and ensure that the machinery operates smoothly under various conditions.

The Role of Electrical Systems in CAT Tracks

Electrical systems in CAT tracks serve multiple purposes. They control hydraulic functions, monitor engine performance, and facilitate communication between various equipment components. For instance, the electrical system helps in managing the hydraulic pumps that drive the machine's movements, allowing for precise action when digging, lifting, or rotating.

Furthermore, these systems are critical for safety. Modern CAT machinery is equipped with sensors that detect operational anomalies or malfunctions. These sensors communicate with the central control unit, which can alert the operator or automatically shut down the system to prevent accidents and equipment damage.

Advances in Technology

cat track electrical

In recent years, the integration of advanced technologies into CAT track electrical systems has improved efficiency significantly. Telematics systems, for example, allow for real-time monitoring of equipment performance. Data on fuel consumption, operating hours, and machine health can be transmitted wirelessly to fleet managers, helping to optimize maintenance schedules and reduce downtime.

Moreover, innovations such as autonomous operation are changing the landscape of construction and mining. Autonomous CAT tracks equipped with advanced electrical systems can perform tasks with minimal human intervention. This not only enhances productivity but also improves safety by reducing the risk of accidents in hazardous environments.

Maintenance and Challenges

While CAT track electrical systems are designed for durability and reliability, they still require regular maintenance to ensure optimal performance. Routine checks on wiring, connectors, and sensors are essential to identify potential issues before they lead to significant problems. Regular diagnostics can help maintain system integrity and reduce costly repairs or downtime.

Challenges do exist, particularly with the increasing complexity of electronic systems. As technology evolves, technicians must stay updated on new systems and diagnostic tools. Adequate training is essential to equip workforce members with the necessary skills to troubleshoot and repair modern electrical systems effectively.

Conclusion

The advancements in CAT track electrical systems represent a significant leap forward in machinery technology, providing enhanced efficiency, safety, and productivity. As industries continue to embrace automation and digital innovations, the importance of robust and reliable electrical systems will only grow. By investing in maintenance and training, companies can ensure that their CAT equipment remains at the forefront of technological excellence, ready to meet the challenges of tomorrow's construction and mining projects. Embracing these systems not only drives operational success but also contributes to a more sustainable and efficient future in heavy machinery.