Leading Chip Conveyor Manufacturers | Efficient Solutions for Metalworking

Understanding Chip Conveyor Manufacturers

Chip conveyors play a crucial role in modern manufacturing processes, particularly in the machining industry where metal chips and other by-products are generated during the production of parts and components. These conveyors are engineered specifically to transport these waste materials away from machining areas, providing a cleaner and more efficient work environment, while also ensuring the continuous operation of machinery. As industries increasingly focus on automation and efficiency, the demand for reliable chip conveyor manufacturers has grown significantly.

What to Look for in Chip Conveyor Manufacturers

When choosing a chip conveyor manufacturer, there are several key factors to consider. First, the type of material handling required must be assessed. Chip conveyors can be categorically divided into various types—like belt conveyors, screw conveyors, magnetic conveyors, and drag conveyors—each designed to handle specific chip types and sizes. A quality manufacturer will offer a range of products tailored to different industrial needs.

Secondly, the experience and reputation of the manufacturer in the industry are vital. Established manufacturers often have proven track records, extensive customer bases, and expertise in optimizing conveyor systems for different applications. Looking into customer reviews and testimonials can provide insights into the reliability and quality of a manufacturer's products.

Another important factor is customization. Different manufacturing processes produce different types of chips, requiring varied solutions for chip removal. A reputable chip conveyor manufacturer will offer customizable options to ensure the conveyor system meets the specific needs of your production line.

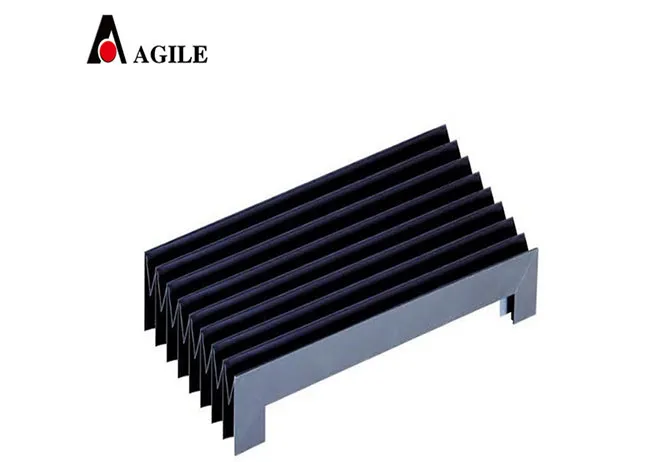

chip conveyor manufacturers

Innovation and Technology in Chip Conveyors

The advancement of technology has significantly transformed the design and functionality of chip conveyors. Modern manufacturers are harnessing the power of automation and smart technology to create more efficient systems. Features such as sensors for monitoring chip buildup, automated controls for system operation, and real-time data transmission for maintenance alerts can greatly enhance productivity and reduce downtime.

Additionally, sustainability is becoming an integral part of manufacturing processes. Manufacturers that prioritize environmentally friendly practices—such as creating conveyors that minimize energy consumption or are made from recyclable materials—can provide a competitive edge in today’s eco-conscious market.

Conclusion

In conclusion, chip conveyor manufacturers are essential partners in manufacturing and machining industries, providing crucial solutions for waste management and process efficiency. Selecting the right manufacturer involves considering factors such as type of conveyors offered, industry experience, customization options, and commitment to innovation and sustainability. As the industry continues to evolve, the most successful chip conveyor manufacturers will be those who adapt to new technologies and meet the changing needs of their customers. By investing in high-quality chip conveyor systems, manufacturers can streamline their operations, improve productivity, and contribute to a cleaner, more sustainable manufacturing environment.