Innovative Solutions for Chip Screw Conveyor Design and Efficiency Optimization

The Versatility of Chip Screw Conveyors in Modern Industry

Chip screw conveyors are essential components in various industrial applications, particularly in manufacturing and processing environments where the efficient transportation of bulk materials is crucial. These conveyors are designed to handle diverse materials, including metal shavings, wood chips, grain, and more. The unique design and functionality of chip screw conveyors make them an indispensable tool across multiple sectors, from metalworking to agriculture.

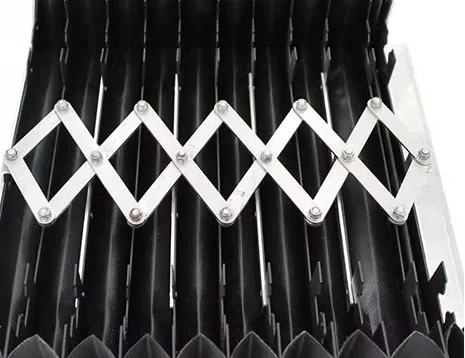

At the core of a chip screw conveyor is its helical screw blade, which is housed within a trough or tube. This design allows for efficient material movement along a predetermined path. As the screw rotates, the material is lifted and propelled forward, minimizing the chances of blockages and ensuring a continuous flow. The versatility of these conveyors lies in their ability to transport materials at different angles and heights, making them suitable for a wide range of applications.

One of the most common uses of chip screw conveyors is in the metalworking industry. During machining processes, significant amounts of metal chips are produced. Traditional methods of handling these chips can be labor-intensive and inefficient, leading to workplace hazards and increased downtime. Chip screw conveyors streamline this process by automating the removal of chips from machines, transporting them directly to a collection bin or recycling unit. This not only enhances workplace safety by reducing the risk of slips and falls but also improves efficiency by minimizing interruptions during the machining process.

In addition to their role in metalworking, chip screw conveyors are also widely used in woodworking operations. The production of wood chips, sawdust, and other by-products generates a high volume of waste materials that need to be managed effectively. Chip screw conveyors can transport these materials to a designated area for processing or disposal, significantly reducing handling time and improving overall workflow in wooden product manufacturing.

chip screw conveyor

Agricultural applications have also found a place for chip screw conveyors. They are employed in the transportation of grains and seeds, where their ability to handle bulk materials makes them invaluable. The adjustable design of screw conveyors allows for customization based on the specific material being transported, ensuring optimal flow and minimizing degradation during handling.

One of the standout features of chip screw conveyors is their adaptability. They can be designed to work in conjunction with other machinery, such as shredders, grinders, and balers, creating a seamless material handling system. Additionally, they can be built to various lengths and diameters to accommodate specific operational needs, demonstrating their flexibility in design.

However, despite their numerous advantages, chip screw conveyors do have their limitations. One potential issue is the wear and tear on the screw and trough over time, especially when handling abrasive materials. Regular maintenance and periodic inspections are essential to ensure the longevity and efficiency of these systems.

In conclusion, chip screw conveyors play a vital role in enhancing productivity and safety within various industries. Their ability to efficiently transport materials while minimizing labor costs and downtime makes them a crucial component in modern manufacturing and processing environments. As industries continue to evolve, the demand for innovative material handling solutions like chip screw conveyors is likely to increase, and their role in shaping efficient operational workflows cannot be overstated.