cnc bellows

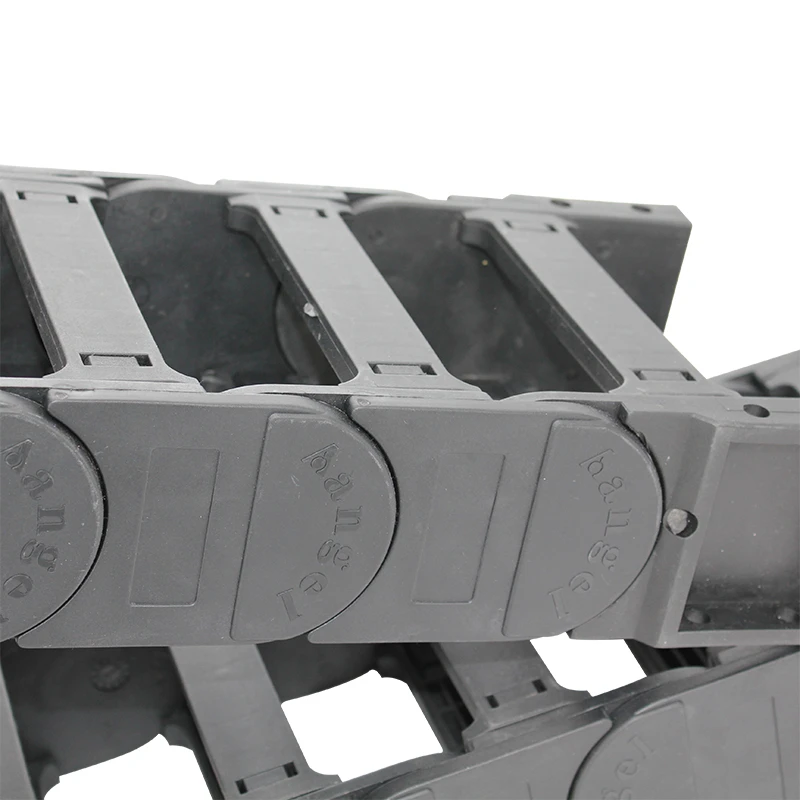

CNC bellows, a cornerstone in the realm of advanced manufacturing, have become indispensable for safeguarding precision tools. These protective covers provide essential shielding for CNC machinery, guarding against contaminants such as dust, metal shavings, and coolant damage. Their efficacy not only prolongs machinery lifespan but also ensures optimal performance, reducing unnecessary maintenance downtime.

The authoritativeness of CNC bellows is well-documented in numerous industrial studies. Research highlights their role in increasing the precision of machined parts by maintaining a contaminant-free working environment. For industries where tolerance levels are critical, such as aerospace or automotive manufacturing, bellows provide an indispensable line of defense. By minimizing fluctuations in machine calibration due to external factors, they ensure that every cut and movement is executed with maximum precision. Trustworthiness and reliability of CNC bellows are founded on decades of technological development. Leading manufacturers employ rigorous testing protocols, simulating extreme operating conditions to validate the durability of their products. Some modern CNC bellows feature design enhancements such as reinforced edges and custom sealing options, which further augment their protective capabilities. Customer testimonials frequently underscore the trust placed in these protective solutions. A large-scale manufacturer, for instance, reported a 30% reduction in maintenance costs after implementing CNC bellows. Such firsthand accounts reinforce their value proposition, assuring potential buyers of tangible benefits. CNC bellows are thus a strategic investment for any facility prioritizing machine longevity and efficiency. By deploying these covers, operators fortify their machinery against the inevitable challenges of industrial environments. With advancements in material science and manufacturing techniques, the future of CNC bellows looks promising, poised to deliver ever greater protection and performance enhancements.

The authoritativeness of CNC bellows is well-documented in numerous industrial studies. Research highlights their role in increasing the precision of machined parts by maintaining a contaminant-free working environment. For industries where tolerance levels are critical, such as aerospace or automotive manufacturing, bellows provide an indispensable line of defense. By minimizing fluctuations in machine calibration due to external factors, they ensure that every cut and movement is executed with maximum precision. Trustworthiness and reliability of CNC bellows are founded on decades of technological development. Leading manufacturers employ rigorous testing protocols, simulating extreme operating conditions to validate the durability of their products. Some modern CNC bellows feature design enhancements such as reinforced edges and custom sealing options, which further augment their protective capabilities. Customer testimonials frequently underscore the trust placed in these protective solutions. A large-scale manufacturer, for instance, reported a 30% reduction in maintenance costs after implementing CNC bellows. Such firsthand accounts reinforce their value proposition, assuring potential buyers of tangible benefits. CNC bellows are thus a strategic investment for any facility prioritizing machine longevity and efficiency. By deploying these covers, operators fortify their machinery against the inevitable challenges of industrial environments. With advancements in material science and manufacturing techniques, the future of CNC bellows looks promising, poised to deliver ever greater protection and performance enhancements.