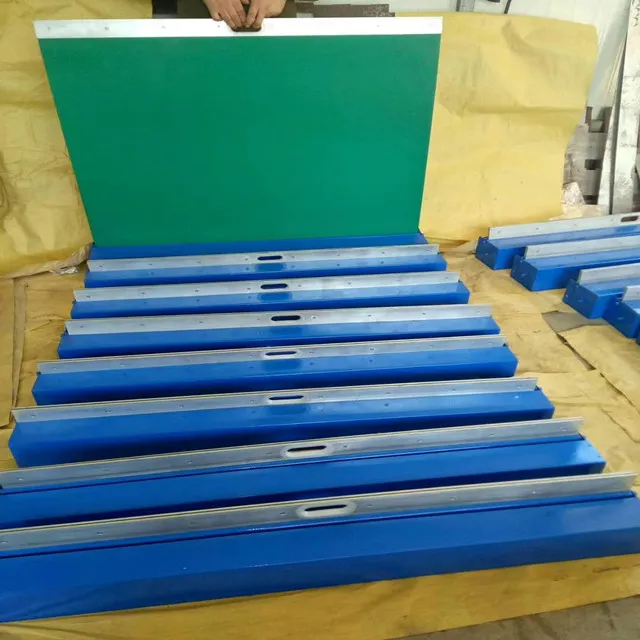

60*150 mm MT open type nylon flexible both side openable cable chain

CNC cable carriers, an essential component within industrial machinery, play a critical role in maintaining the durability and functionality of CNC equipment. These devices, also known as drag chains or energy chains, are engineered to support and protect moving cables and hoses, preventing damage that could lead to costly downtime and repairs. Through years of industrial experience and deep technical knowledge, it's clear that selecting the right CNC cable carrier requires attention to several key factors that influence performance and longevity.

The importance of an expertly engineered design in CNC cable carriers cannot be understated when considering factors related to wear protection and noise reduction. Innovative technologies in design have led to carriers that not only protect cables but also significantly reduce the noise produced by machines. This advancement is particularly beneficial in industries where noise pollution is a concern and a quieter workspace is desired. In establishing trustworthiness and authority, many industry leaders emphasize the need for proper installation and regular maintenance of CNC cable carriers. Proper installation ensures optimal performance and reduces the likelihood of mechanical failure. Regular inspection and maintenance routines can identify signs of wear or damage early on, preventing unexpected machine downtimes. The growing adoption of Industry 4.0 practices further highlights the importance of integrating smart solutions in CNC cable carriers. Modern carriers now incorporate smart sensors to monitor conditions such as temperature, vibration, and pull force on cables. Such innovations allow for predictive maintenance, significantly enhancing the lifespan and reliability of CNC machinery. To conclude, the selection and maintenance of CNC cable carriers demand a comprehensive understanding of both the operational mechanics and environmental conditions unique to each application. Expertise, built over years of practical involvement and technical knowledge, informs the decision-making process, ensuring that the chosen solution aligns perfectly with industrial needs. As industries continue to evolve, leveraging cutting-edge technologies and best practices in cable carrier systems will undeniably empower businesses to enhance operational efficiencies and maintain a competitive edge.

The importance of an expertly engineered design in CNC cable carriers cannot be understated when considering factors related to wear protection and noise reduction. Innovative technologies in design have led to carriers that not only protect cables but also significantly reduce the noise produced by machines. This advancement is particularly beneficial in industries where noise pollution is a concern and a quieter workspace is desired. In establishing trustworthiness and authority, many industry leaders emphasize the need for proper installation and regular maintenance of CNC cable carriers. Proper installation ensures optimal performance and reduces the likelihood of mechanical failure. Regular inspection and maintenance routines can identify signs of wear or damage early on, preventing unexpected machine downtimes. The growing adoption of Industry 4.0 practices further highlights the importance of integrating smart solutions in CNC cable carriers. Modern carriers now incorporate smart sensors to monitor conditions such as temperature, vibration, and pull force on cables. Such innovations allow for predictive maintenance, significantly enhancing the lifespan and reliability of CNC machinery. To conclude, the selection and maintenance of CNC cable carriers demand a comprehensive understanding of both the operational mechanics and environmental conditions unique to each application. Expertise, built over years of practical involvement and technical knowledge, informs the decision-making process, ensuring that the chosen solution aligns perfectly with industrial needs. As industries continue to evolve, leveraging cutting-edge technologies and best practices in cable carrier systems will undeniably empower businesses to enhance operational efficiencies and maintain a competitive edge.