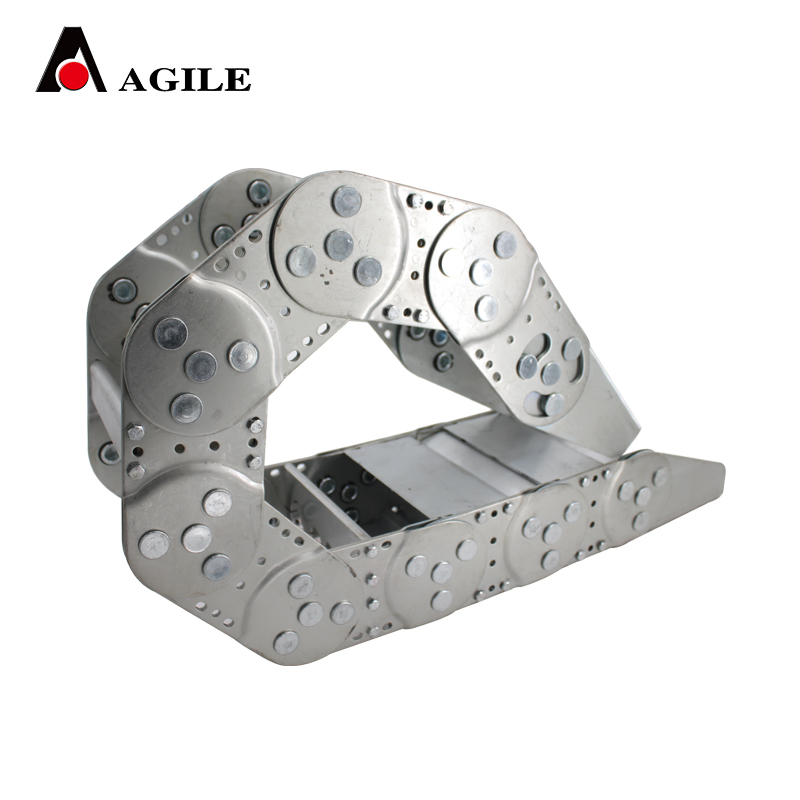

flexible cable carrier

CNC cable carriers play a pivotal role in the efficient operation of automated machinery. These mechanical devices protect and guide electric cables and hydraulic or pneumatic hoses connected to automated machinery. Selecting the right cable carrier can significantly influence the longevity and performance of the CNC machine, making it an essential consideration for those concerned with production efficiency and machine reliability.

An authoritative take on CNC cable carriers also involves the understanding of their specific configurations. Open versus closed systems, for instance, offer different levels of protection and flexibility. Open systems are easier for maintenance and modifications, while closed systems provide superior protection for the cables from debris or environmental hazards. Deciding on the configuration requires an assessment of the specific application needs and operational environment of your CNC machinery. Trust is an indispensable facet of implementing a CNC cable carrier solution. Installing a well-trusted and time-tested cable carrier from reputable manufacturers can alleviate concerns about unexpected failures and reduce the long-term costs associated with equipment maintenance. Relying on established brands with a track history of quality engineering ensures a stable and effective integration into existing systems. Incorporating user experience into the equation, it's recommended to seek feedback from operators and technicians who interact with the machinery daily. Their insights can highlight practical considerations that may affect carrier performance. Experienced operators can often provide invaluable feedback regarding the ease of installation, maintenance requirements, and any operational quirks unique to a given CNC setup. The role of CNC cable carriers in the industrial ecosystem goes beyond mere utility. They are a critical component in maintaining operational efficiency, reducing maintenance costs, and ensuring safety. As such, professionals responsible for selecting cable carriers should leverage a mixture of hands-on experience, industry expertise, authoritative resources, and a solid reputation to ensure that their choices align with the overarching goals of productivity and reliability.

An authoritative take on CNC cable carriers also involves the understanding of their specific configurations. Open versus closed systems, for instance, offer different levels of protection and flexibility. Open systems are easier for maintenance and modifications, while closed systems provide superior protection for the cables from debris or environmental hazards. Deciding on the configuration requires an assessment of the specific application needs and operational environment of your CNC machinery. Trust is an indispensable facet of implementing a CNC cable carrier solution. Installing a well-trusted and time-tested cable carrier from reputable manufacturers can alleviate concerns about unexpected failures and reduce the long-term costs associated with equipment maintenance. Relying on established brands with a track history of quality engineering ensures a stable and effective integration into existing systems. Incorporating user experience into the equation, it's recommended to seek feedback from operators and technicians who interact with the machinery daily. Their insights can highlight practical considerations that may affect carrier performance. Experienced operators can often provide invaluable feedback regarding the ease of installation, maintenance requirements, and any operational quirks unique to a given CNC setup. The role of CNC cable carriers in the industrial ecosystem goes beyond mere utility. They are a critical component in maintaining operational efficiency, reducing maintenance costs, and ensuring safety. As such, professionals responsible for selecting cable carriers should leverage a mixture of hands-on experience, industry expertise, authoritative resources, and a solid reputation to ensure that their choices align with the overarching goals of productivity and reliability.