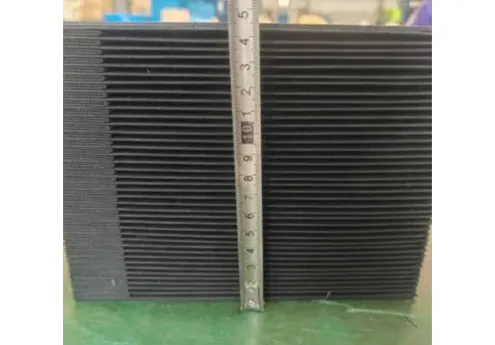

cnc cable track

Navigating the realm of CNC cable tracks can significantly enhance your machinery's performance and reliability. As pivotal components in CNC machinery, cable tracks safeguard cables and hoses, streamlining operations while minimizing wear and tear. Through extensive research and years of experience in industrial automation, we’ve compiled vital insights to help you make informed decisions about cable tracks' procurement and integration.

Trustworthiness in your supplier cannot be overstated. A reputable supplier offers more than just products; they provide guidance grounded in proven results and reliability. When exploring suppliers, look for those with a solid track record, positive client testimonials, and clear assurances of quality through certifications like ISO standards. Such credentials ensure that you invest in cable tracks engineered to meet or exceed industry expectations. Selecting CNC cable tracks is not a mere transactional decision; it's a strategic move to bolster your operational infrastructure. By prioritizing quality and compatibility, you invest in a system that ensures constant uptime, enhances machine efficiency, and promotes sustainable operations. Through deepening your understanding of cable track mechanics and leveraging expert advice, your equipment reaps the benefits of reduced frictional impacts and enhanced workflow efficiency. In conclusion, the path to mastering CNC cable track implementation lies in accumulating knowledge and practical application. By aligning your choices with the overarching objectives of durability, precision, and reliability, you position your business to harness the full potential of your CNC machinery. For any enterprise keen on enhancing its operational precision, the conscious selection of cable tracks marks a critical step towards achieving these goals and securing a competitive edge in the market.

Trustworthiness in your supplier cannot be overstated. A reputable supplier offers more than just products; they provide guidance grounded in proven results and reliability. When exploring suppliers, look for those with a solid track record, positive client testimonials, and clear assurances of quality through certifications like ISO standards. Such credentials ensure that you invest in cable tracks engineered to meet or exceed industry expectations. Selecting CNC cable tracks is not a mere transactional decision; it's a strategic move to bolster your operational infrastructure. By prioritizing quality and compatibility, you invest in a system that ensures constant uptime, enhances machine efficiency, and promotes sustainable operations. Through deepening your understanding of cable track mechanics and leveraging expert advice, your equipment reaps the benefits of reduced frictional impacts and enhanced workflow efficiency. In conclusion, the path to mastering CNC cable track implementation lies in accumulating knowledge and practical application. By aligning your choices with the overarching objectives of durability, precision, and reliability, you position your business to harness the full potential of your CNC machinery. For any enterprise keen on enhancing its operational precision, the conscious selection of cable tracks marks a critical step towards achieving these goals and securing a competitive edge in the market.