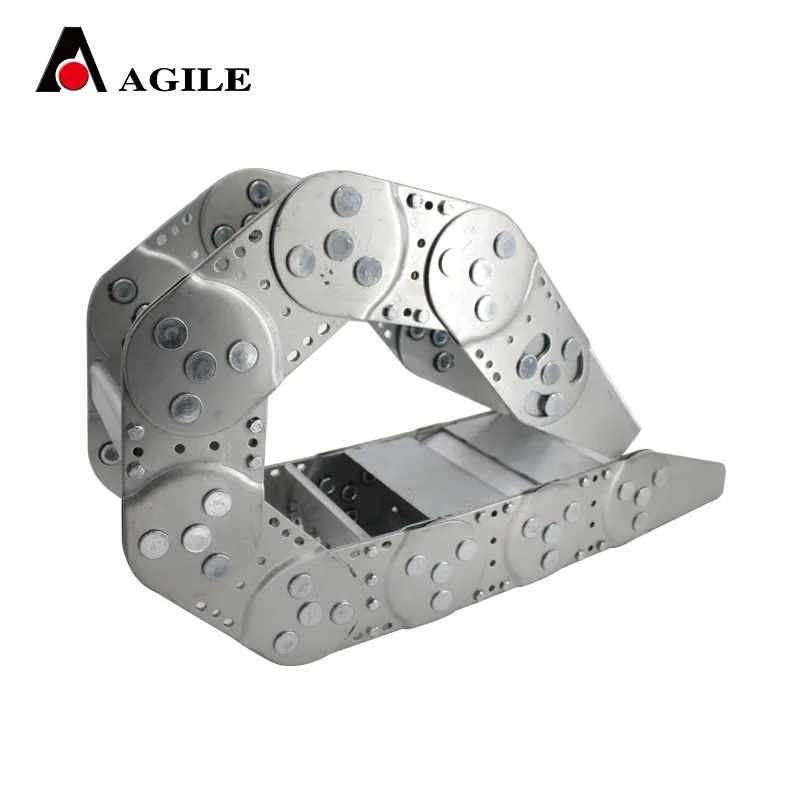

25*75 mm MTK reinforced bridge type both side openable energy chain

CNC drag chains are indispensable components in the realm of modern manufacturing and automation. Imagine a symphony orchestra where each musician’s contribution is critical for creating harmonies; similarly, drag chains ensure seamless operation by organizing cables in CNC machinery, which is crucial for the harmonious function of intricate processes. Beyond their apparent simplicity as cable carriers, these chains embody technological expertise, reliability, and superior design, setting benchmarks in industrial applications.

Moreover, drag chains play a vital role in the growing domain of smart manufacturing. With the integration of IoT (Internet of Things) technologies, modern drag chains can be equipped with sensors facilitating real-time monitoring of vibrational patterns and temperature fluctuations. This intelligent feedback loop enhances predictive maintenance, allowing manufacturers to preemptively address issues before they escalate into costly downtimes. This advanced level of monitoring underscores the technological sophistication and foresight exemplified by leading manufacturers. In terms of environmental considerations, some manufacturers are championing sustainability by designing drag chains that are recyclable and adopting manufacturing processes that reflect ecological responsibility. The market is witnessing a gradual shift towards eco-friendly solutions that do not compromise on quality or performance, aligning innovation with environmental stewardship. Selecting the right drag chain is akin to crafting a blueprint for performance excellence. Understanding the operational parameters—such as travel length, speed, and acceleration of the machinery—enables engineers to tailor solutions that align with operational goals. Additionally, paying close attention to factors such as bending radius and strength ensures that the drag chain supports the lifecycle of the CNC machine it complements. Expounding on the expertise shared by engineers, the advantages offered by CNC drag chains are multifaceted. They enhance process safety by reducing risks linked with cable entanglement and wear. By channeling cables purposefully and preventing overlap, drag chains are instrumental in preserving the integrity of complex electrical systems. Thus, CNC drag chains are more than mere cable carriers; they are the epitome of planning, engineering prowess, and precision. They encapsulate the qualities of a meticulously orchestrated system where each component plays its part in elevating manufacturing processes to new pinnacles of efficiency and reliability. The future of CNC machining lies in innovation, and at its core, the humble drag chain holds profound significance, remaining indispensable amidst the evolving contours of industrial engineering.

Moreover, drag chains play a vital role in the growing domain of smart manufacturing. With the integration of IoT (Internet of Things) technologies, modern drag chains can be equipped with sensors facilitating real-time monitoring of vibrational patterns and temperature fluctuations. This intelligent feedback loop enhances predictive maintenance, allowing manufacturers to preemptively address issues before they escalate into costly downtimes. This advanced level of monitoring underscores the technological sophistication and foresight exemplified by leading manufacturers. In terms of environmental considerations, some manufacturers are championing sustainability by designing drag chains that are recyclable and adopting manufacturing processes that reflect ecological responsibility. The market is witnessing a gradual shift towards eco-friendly solutions that do not compromise on quality or performance, aligning innovation with environmental stewardship. Selecting the right drag chain is akin to crafting a blueprint for performance excellence. Understanding the operational parameters—such as travel length, speed, and acceleration of the machinery—enables engineers to tailor solutions that align with operational goals. Additionally, paying close attention to factors such as bending radius and strength ensures that the drag chain supports the lifecycle of the CNC machine it complements. Expounding on the expertise shared by engineers, the advantages offered by CNC drag chains are multifaceted. They enhance process safety by reducing risks linked with cable entanglement and wear. By channeling cables purposefully and preventing overlap, drag chains are instrumental in preserving the integrity of complex electrical systems. Thus, CNC drag chains are more than mere cable carriers; they are the epitome of planning, engineering prowess, and precision. They encapsulate the qualities of a meticulously orchestrated system where each component plays its part in elevating manufacturing processes to new pinnacles of efficiency and reliability. The future of CNC machining lies in innovation, and at its core, the humble drag chain holds profound significance, remaining indispensable amidst the evolving contours of industrial engineering.