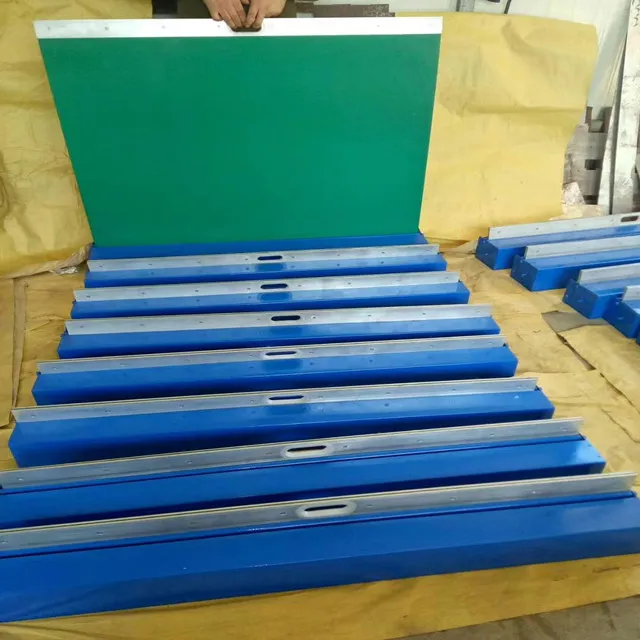

cnc machine bellow covers

The Importance of CNC Machine Bellows Covers

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, providing precision and efficiency in the machining process. One often overlooked yet crucial component of these machines is the bellows cover. Bellows covers serve as protective barriers that safeguard the intricate parts of CNC machines from various contaminants, ensuring their longevity and optimal performance.

The Importance of CNC Machine Bellows Covers

One of the primary benefits of using bellows covers is the reduction of maintenance costs. By keeping contaminants away from critical components, these covers help to minimize wear on linear guides, ballscrews, and other moving parts. This not only extends the lifespan of these components but also reduces the frequency of repairs and downtime. In the competitive landscape of manufacturing, minimizing downtime is crucial for maintaining productivity and meeting delivery deadlines.

cnc machine bellow covers

In addition to protection and cost savings, bellows covers can improve the overall safety of the working environment. By containing chips and coolant within their confines, they help to maintain a cleaner workspace, reducing the risk of slips and falls. Furthermore, they can prevent accidental contact with moving parts, ensuring that operators are safe while the machine is in operation.

When selecting bellows covers for CNC machines, it is essential to consider factors such as the operating environment, the type of materials used, and the machine’s specifications. Custom-made bellows covers can provide the best fit and functionality, tailored to the unique needs of different CNC applications.

In summary, bellows covers are a vital component of CNC machines, contributing to their performance, safety, and maintenance efficiency. By investing in high-quality bellows covers, manufacturers can enhance their operational capabilities and ensure that their machines run smoothly for years to come.