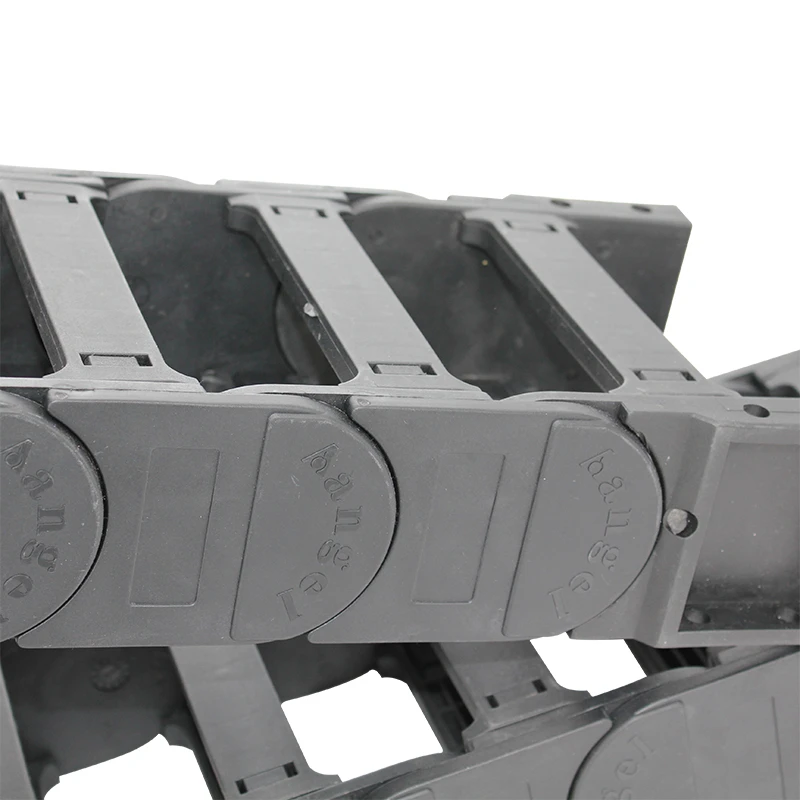

corrugated conduit

Corrugated conduit might seem like a basic component in the world of electrical and communication infrastructure, but its significance is both profound and largely underestimated. The innovation and engineering behind this product illuminate its importance far beyond its simple appearance. The article sheds light on the nuances that make corrugated conduit indispensable, drawing from expert insights and real-world experiences to highlight its trustworthiness and authority in the industry.

Real-world applications of corrugated conduits underscore their versatility and indispensability. Their use spans a wide range of sectors, from residential projects to large-scale industrial installations. A prominent example is their employment in data centers, where millions of cables are organized into complex networks. Here, corrugated conduits not only streamline the installation process but also enable straightforward management and future expansion without the fear of damaging existing networks. The efficacy of corrugated conduits extends to public infrastructure as well. In urban settings, the demand for efficient, reliable public utilities is relentless. Corrugated conduits are often used to protect underground electrical networks and water pipelines. Their resilience against environmental pressures makes them ideal for such demanding applications, where failure could lead to significant public disruption. In the arena of green construction, corrugated conduits are gaining traction as well. Advancements in eco-friendly materials have led to the development of biodegradable and recyclable options, aligning with sustainable building practices. The capacity to balance infrastructure needs with environmental stewardship makes corrugated conduits an attractive choice for projects aiming for LEED certification or similar green standards. However, it is not just the product’s material and design that contribute to its authority in the field. The manufacturers behind these conduits perpetually advance their products through rigorous testing and compliance with international standards. ISO certifications and similar credentials fortify the trust that contractors and engineers place in corrugated conduits, ensuring they meet or exceed safety and performance expectations. In conclusion, corrugated conduits, through their blend of flexibility, resilience, and protective capabilities, stand out as a crucial component in modern construction and infrastructure projects. Their expert design safeguards not only essential utilities but also the investments and well-being of those who depend on them. Understanding the layers of technology and innovation behind this everyday object reinforces its indispensable nature in building the infrastructure of tomorrow.

Real-world applications of corrugated conduits underscore their versatility and indispensability. Their use spans a wide range of sectors, from residential projects to large-scale industrial installations. A prominent example is their employment in data centers, where millions of cables are organized into complex networks. Here, corrugated conduits not only streamline the installation process but also enable straightforward management and future expansion without the fear of damaging existing networks. The efficacy of corrugated conduits extends to public infrastructure as well. In urban settings, the demand for efficient, reliable public utilities is relentless. Corrugated conduits are often used to protect underground electrical networks and water pipelines. Their resilience against environmental pressures makes them ideal for such demanding applications, where failure could lead to significant public disruption. In the arena of green construction, corrugated conduits are gaining traction as well. Advancements in eco-friendly materials have led to the development of biodegradable and recyclable options, aligning with sustainable building practices. The capacity to balance infrastructure needs with environmental stewardship makes corrugated conduits an attractive choice for projects aiming for LEED certification or similar green standards. However, it is not just the product’s material and design that contribute to its authority in the field. The manufacturers behind these conduits perpetually advance their products through rigorous testing and compliance with international standards. ISO certifications and similar credentials fortify the trust that contractors and engineers place in corrugated conduits, ensuring they meet or exceed safety and performance expectations. In conclusion, corrugated conduits, through their blend of flexibility, resilience, and protective capabilities, stand out as a crucial component in modern construction and infrastructure projects. Their expert design safeguards not only essential utilities but also the investments and well-being of those who depend on them. Understanding the layers of technology and innovation behind this everyday object reinforces its indispensable nature in building the infrastructure of tomorrow.