corrugated plastic tubing automotive

The Importance of Corrugated Plastic Tubing in the Automotive Industry

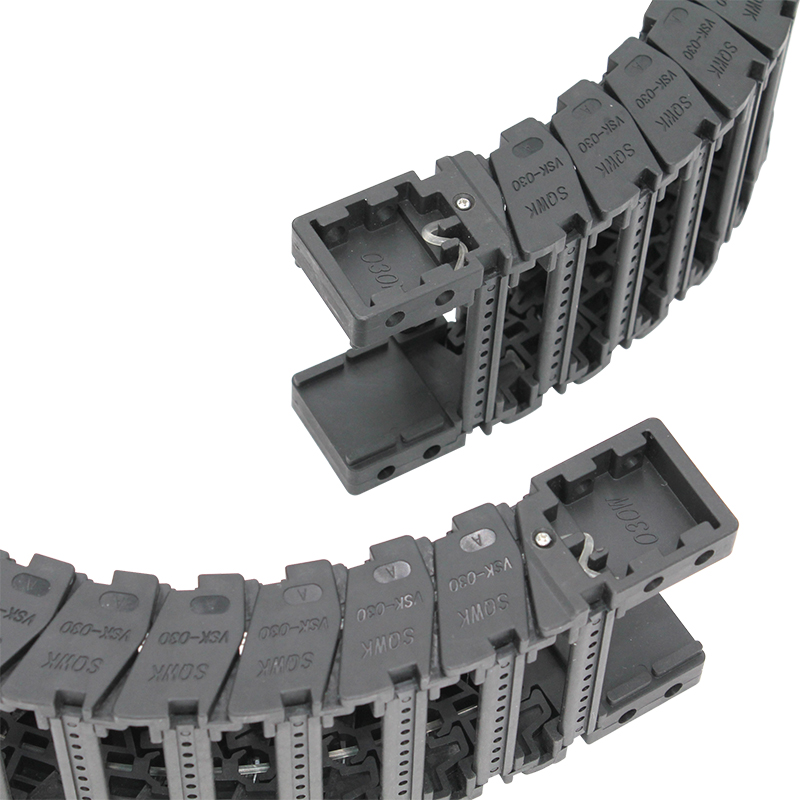

Corrugated plastic tubing has emerged as a crucial component in the automotive sector, providing numerous advantages that enhance vehicle performance and safety. This innovative material, often made from high-density polyethylene (HDPE), has become increasingly popular due to its lightweight, flexibility, and durability. As automotive manufacturers strive for efficiency and sustainability, the use of corrugated plastic tubing is on the rise.

One of the primary benefits of corrugated plastic tubing is its lightweight nature. Traditional metal or rubber hoses can add unnecessary weight to vehicles, impacting overall fuel efficiency. In contrast, corrugated plastic tubing significantly reduces weight while maintaining high tensile strength. This reduction in weight can lead to improved fuel consumption and lower emissions, aligning with the industry's push towards greener and more eco-friendly vehicles.

Additionally, corrugated plastic tubing is renowned for its flexibility. This characteristic allows the tubing to be easily routed through the complicated layouts of modern vehicles, accommodating the tight spaces and intricate designs without the risk of kinking or collapsing. This flexibility is especially crucial in applications involving fluid transportation, such as coolant, fuel, and air intake systems. The ability to bend and twist without compromising structural integrity makes corrugated plastic tubing an ideal choice for various automotive applications.

corrugated plastic tubing automotive

Durability is another vital feature of corrugated plastic tubing. It offers excellent resistance to chemicals, UV light, and extreme temperatures, which are common in automotive environments. This resistance ensures a longer lifespan compared to traditional materials, reducing the need for frequent replacements and maintenance. Moreover, the tubing's water resistance protects against moisture, minimizing the risk of corrosion and enhancing vehicle reliability.

In terms of installation, corrugated plastic tubing is not only lightweight but also easy to handle. Its design allows for quick and simple installations, which can reduce labor costs during manufacturing. The ease of integration into existing systems makes it a favored choice among automotive engineers and manufacturers.

Furthermore, as the automotive industry continues to explore innovative solutions for performance enhancement and sustainability, corrugated plastic tubing is well-positioned to play a significant role. Its compatibility with cutting-edge technologies, such as electric vehicles and hybrid systems, further reinforces its versatility.

In conclusion, corrugated plastic tubing is revolutionizing the automotive industry by offering a lightweight, flexible, and durable solution for various applications. As vehicles become more advanced and the demand for efficient, sustainable products rises, the importance of corrugated plastic tubing will undoubtedly continue to grow, showcasing its value in modern automotive design and engineering.