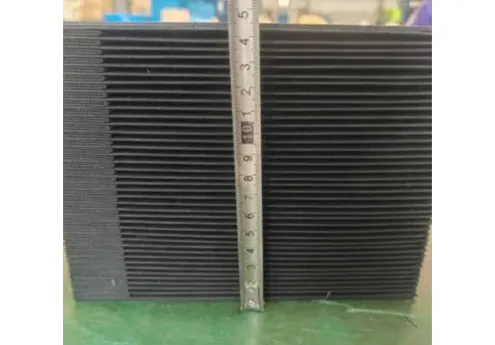

nylon flexible wire loom corrugated bellow conduit hose pipe

Corrugated flexible tubes are vital components in numerous industrial applications, revered for their adaptability and resilience under various conditions. Their structure, characterized by a series of parallel ridges and grooves, provides both flexibility and strength, making them indispensable in several sectors, including construction, automotive, and plumbing.

Innovations in manufacturing processes have further enhanced the performance metrics of corrugated flexible tubes. Advanced extrusion techniques and precision engineering have led to improvements in dimensional accuracy and structural integrity. This evolution has broadened their applicability across industries, creating products tailored to specific operational requirements, whether for high-pressure fluid transfer or sensitive electrical installations. Consumers and industries alike should prioritize sourcing from reputable manufacturers who adhere to rigorous quality standards. Such companies typically provide comprehensive documentation and testing data, ensuring that their products meet both regulatory requirements and industry benchmarks. This level of quality assurance not only guarantees performance but also builds trust with clients and end-users. When integrating corrugated flexible tubes into any system, attention must be given to proper installation and maintenance practices. Ensuring that the tubes are not subjected to excessive bending or stretching extends their operational lifespan. Additionally, regular inspections for signs of wear or damage can prevent costly downtime or system failures, underscoring the importance of adhering to manufacturer guidelines and recommendations. The adaptability and resilience of corrugated flexible tubes make them an essential component in modern engineering and industrial processes. Their ability to withstand diverse environmental challenges while maintaining structural integrity positions them as a reliable and efficient solution across various sectors. As industries push towards more sustainable and efficient practices, the role of these tubes in achieving those goals remains significant, underpinned by continuous innovation and commitment to quality in their production and application.

Innovations in manufacturing processes have further enhanced the performance metrics of corrugated flexible tubes. Advanced extrusion techniques and precision engineering have led to improvements in dimensional accuracy and structural integrity. This evolution has broadened their applicability across industries, creating products tailored to specific operational requirements, whether for high-pressure fluid transfer or sensitive electrical installations. Consumers and industries alike should prioritize sourcing from reputable manufacturers who adhere to rigorous quality standards. Such companies typically provide comprehensive documentation and testing data, ensuring that their products meet both regulatory requirements and industry benchmarks. This level of quality assurance not only guarantees performance but also builds trust with clients and end-users. When integrating corrugated flexible tubes into any system, attention must be given to proper installation and maintenance practices. Ensuring that the tubes are not subjected to excessive bending or stretching extends their operational lifespan. Additionally, regular inspections for signs of wear or damage can prevent costly downtime or system failures, underscoring the importance of adhering to manufacturer guidelines and recommendations. The adaptability and resilience of corrugated flexible tubes make them an essential component in modern engineering and industrial processes. Their ability to withstand diverse environmental challenges while maintaining structural integrity positions them as a reliable and efficient solution across various sectors. As industries push towards more sustainable and efficient practices, the role of these tubes in achieving those goals remains significant, underpinned by continuous innovation and commitment to quality in their production and application.