Automotive Applications of Corrugated Plastic Tubing for Enhanced Durability and Flexibility

The Advantages of Corrugated Plastic Tubing in the Automotive Industry

In the ever-evolving automotive industry, innovation plays a crucial role in enhancing vehicle performance, safety, and efficiency. One innovative material that has increasingly gained prominence is corrugated plastic tubing. This versatile product provides a plethora of benefits that cater to various automotive applications, revolutionizing the way manufacturers approach design and functionality.

The Advantages of Corrugated Plastic Tubing in the Automotive Industry

One major advantage of corrugated plastic tubing is its resistance to chemicals and environmental stressors. In vehicles, tubing is often subjected to various fluids, including oils, fuels, and coolants. The chemical resistance of corrugated plastic prevents degradation and ensures longevity, which is vital for maintaining the reliability of automotive systems. Additionally, the material is resistant to UV radiation, meaning it can withstand exposure to sunlight without deteriorating. This durability translates to lower maintenance costs and longer intervals between replacements, ultimately benefiting both manufacturers and consumers.

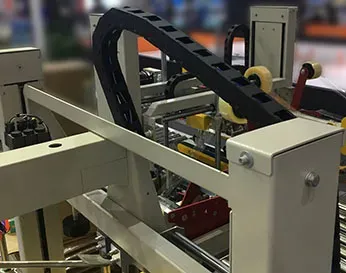

corrugated plastic tubing automotive

Another significant benefit of corrugated plastic tubing is its ability to serve as a protective conduit for electrical wiring and components. In modern vehicles, advanced technology has led to an increase in the amount of wiring necessary for features such as infotainment systems, safety mechanisms, and power distribution. Corrugated plastic tubing provides an effective barrier against moisture, dust, and physical damage, ensuring that wiring systems function optimally in diverse conditions. The flexibility of the tubing allows for streamlined routing of wires, contributing to a cleaner and more organized engine bay or undercarriage.

Also, the manufacturing process for corrugated plastic tubing is relatively simple and cost-effective, which can lead to significant savings in mass production scenarios. The ability to easily cut and mold the tubing into various shapes fosters customization opportunities for automotive manufacturers. Whether it's for air intake systems, battery ventilation, or fluid transfer, the adaptability of corrugated plastic tubing means that engineers can tailor solutions to meet specific requirements without extensive redesign efforts.

Furthermore, as the automotive industry moves towards sustainability, corrugated plastic tubing offers eco-friendly advantages. Many manufacturers are now producing these tubes using recycled materials, which not only lowers the carbon footprint but also promotes a circular economy. In an era where consumers are increasingly conscious of environmental impact, choosing materials with lower ecological footprints can be a positive selling point for automotive companies.

In conclusion, corrugated plastic tubing is carving out an important niche within the automotive industry due to its myriad of benefits, including flexibility, chemical resistance, protection for electrical components, cost-effectiveness, and eco-friendliness. As automotive technology continues to advance and the demand for efficient, durable materials grows, corrugated plastic tubing is poised to play a significant role in shaping the future of vehicle design and manufacturing. The potential for this material indicates that it will remain a key component in the pursuit of innovative and sustainable automotive solutions.