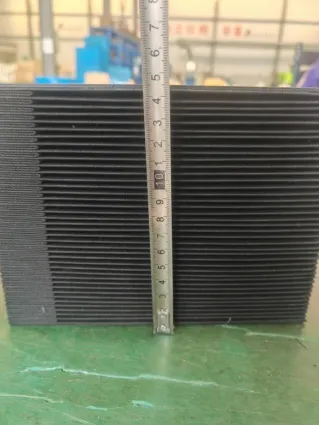

corrugated sleeving

Corrugated sleeving stands as an indispensable component in the protection of wires, cables, and hoses across various industries. Its robust, flexible design ensures superior protection against abrasion, heat, and weeds, making it an ideal choice for environments demanding high durability. Despite the commonality of this product, the application nuances can offer unique insights into optimizing its use for specific projects.

As an authority in protective sleeving solutions, companies have developed standards and certifications to assure customers of the quality and reliability of corrugated sleeving products. These certifications often follow stringent testing for fire resistance, flexibility, and longevity to offer proof of compliance with industry benchmarks. When selecting a provider, verifying these certifications can be instrumental in ensuring product reliability and safety. From a sustainability perspective, advancements in materials science have led to the creation of biodegradable and recyclable sleeving options. These eco-friendly choices do not compromise on performance and prove to be vital in reducing environmental impact, aligning with the increasing corporate mandates for sustainability across sectors. Trust in the application of corrugated sleeving often intertwines with appropriate usage recommendations provided by manufacturers and professional installers. Expertise in the field is distinctively marked by a comprehensive understanding of the compatibility of sleeve types with specific cable materials and the environmental conditions they will face. Ultimately, the expertise required for the optimal use of corrugated sleeving spans across understanding material compatibility, installation precision, and adherence to safety standards. For professionals aiming to maximize cable protection and organization in industrial applications, choosing the right sleeving means evaluating these elements judiciously. With ongoing innovation and a move towards more sustainable solutions, corrugated sleeving remains a definitive choice for protective wrappings in critical operations. Having a profound knowledge in this domain equips professionals to undertake projects with confidence, ensuring not just protection, but efficiency, sustainability, and compliance in their cabling solutions. Users are thereby encouraged to keep abreast of new material technologies and installation methodologies to drive better outcomes in their respective fields.

As an authority in protective sleeving solutions, companies have developed standards and certifications to assure customers of the quality and reliability of corrugated sleeving products. These certifications often follow stringent testing for fire resistance, flexibility, and longevity to offer proof of compliance with industry benchmarks. When selecting a provider, verifying these certifications can be instrumental in ensuring product reliability and safety. From a sustainability perspective, advancements in materials science have led to the creation of biodegradable and recyclable sleeving options. These eco-friendly choices do not compromise on performance and prove to be vital in reducing environmental impact, aligning with the increasing corporate mandates for sustainability across sectors. Trust in the application of corrugated sleeving often intertwines with appropriate usage recommendations provided by manufacturers and professional installers. Expertise in the field is distinctively marked by a comprehensive understanding of the compatibility of sleeve types with specific cable materials and the environmental conditions they will face. Ultimately, the expertise required for the optimal use of corrugated sleeving spans across understanding material compatibility, installation precision, and adherence to safety standards. For professionals aiming to maximize cable protection and organization in industrial applications, choosing the right sleeving means evaluating these elements judiciously. With ongoing innovation and a move towards more sustainable solutions, corrugated sleeving remains a definitive choice for protective wrappings in critical operations. Having a profound knowledge in this domain equips professionals to undertake projects with confidence, ensuring not just protection, but efficiency, sustainability, and compliance in their cabling solutions. Users are thereby encouraged to keep abreast of new material technologies and installation methodologies to drive better outcomes in their respective fields.