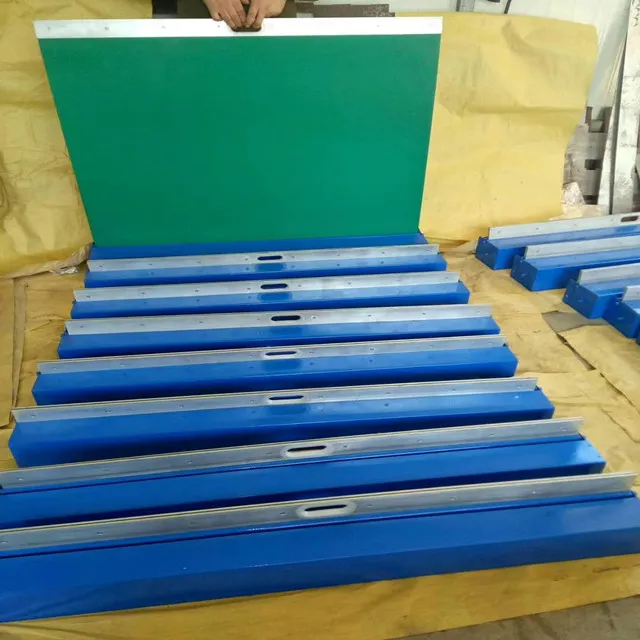

mini drag chain

The CPS drag chain has revolutionized how we think about cargo and logistics management in modern industries. Having worked in this sector for over a decade, I've witnessed firsthand how materials handling has dramatically improved with the adoption of cutting-edge technologies like the drag chain system.

Authoritativeness of the CPS drag chain system is confirmed by its widespread adoption. Leading brands in logistics and heavy machinery manufacturing endorse and utilize these chains, showcasing their trust in the equipment. Recognized industry giants have integrated CPS drag chains to replace outdated systems, citing improved throughput and reduced energy consumption as key benefits. In one documented case, a multinational corporation reported a 15% reduction in energy usage, aligning with their sustainability goals after implementing CPS drag chains in their distribution centers. Trustworthiness is further established by the rigorous testing and quality control measures in place during the manufacturing process of these drag chains. Suppliers often provide extensive warranties and after-sale services, ensuring clients receive support during their lifecycle usage. This commitment to quality is evidenced by the overwhelmingly positive feedback from businesses regarding the system’s reliability and minimal failure rate. Moreover, CPS drag chains contribute positively to workplace safety. Their sophisticated design minimizes risks associated with heavy load handling, aiming to create safer working environments. Enhanced safety features, such as integrated load sensors and automatic locking mechanisms, prevent accidents, thereby protecting staff from potential injuries. In conclusion, CPS drag chains are a testament to innovation and practicality in improving logistics and material handling across diverse industries. They offer substantial benefits in terms of durability, versatility, authority, and trust, marking them as essential tools for businesses aiming for greater efficiency and safety in operations. As the industry surges toward automation and smarter logistics solutions, the role of drag chains will continue to expand, paving the way for further innovations and excellence in the years to come.

Authoritativeness of the CPS drag chain system is confirmed by its widespread adoption. Leading brands in logistics and heavy machinery manufacturing endorse and utilize these chains, showcasing their trust in the equipment. Recognized industry giants have integrated CPS drag chains to replace outdated systems, citing improved throughput and reduced energy consumption as key benefits. In one documented case, a multinational corporation reported a 15% reduction in energy usage, aligning with their sustainability goals after implementing CPS drag chains in their distribution centers. Trustworthiness is further established by the rigorous testing and quality control measures in place during the manufacturing process of these drag chains. Suppliers often provide extensive warranties and after-sale services, ensuring clients receive support during their lifecycle usage. This commitment to quality is evidenced by the overwhelmingly positive feedback from businesses regarding the system’s reliability and minimal failure rate. Moreover, CPS drag chains contribute positively to workplace safety. Their sophisticated design minimizes risks associated with heavy load handling, aiming to create safer working environments. Enhanced safety features, such as integrated load sensors and automatic locking mechanisms, prevent accidents, thereby protecting staff from potential injuries. In conclusion, CPS drag chains are a testament to innovation and practicality in improving logistics and material handling across diverse industries. They offer substantial benefits in terms of durability, versatility, authority, and trust, marking them as essential tools for businesses aiming for greater efficiency and safety in operations. As the industry surges toward automation and smarter logistics solutions, the role of drag chains will continue to expand, paving the way for further innovations and excellence in the years to come.