10*15 mm MT small size mini nylon drag chain

Drag chains, indispensable components in modern manufacturing and automation systems, play a pivotal role in ensuring seamless operations across industries. As a seasoned expert in industrial automation, I have witnessed firsthand the transformative impact of optimized drag chain systems on production efficiency and operational reliability.

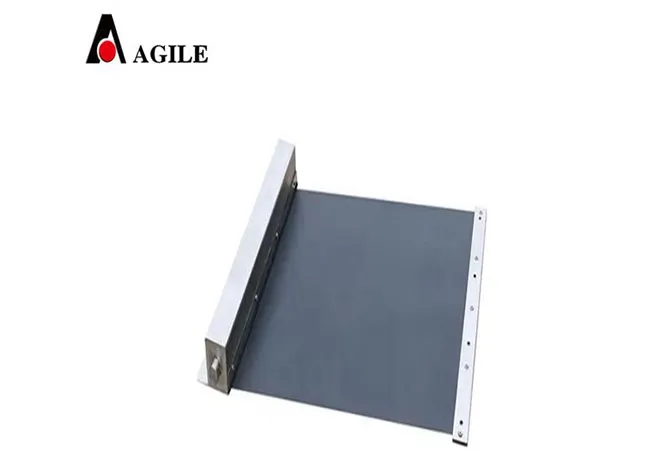

Drag chains, also known as cable carriers or energy chains, house and protect moving cables and hoses, preventing entanglement and ensuring longevity. Their application spans from simple woodworking machines to complex robotic arms in automotive assembly lines. The choice of drag chain material and design can significantly influence system performance and maintenance costs, making expertise in this area invaluable.

Having worked with several manufacturers, I have found that understanding the physical and operational environment is crucial when selecting a drag chain. For instance, in harsh environments with exposure to chemicals or extreme temperatures, specialized materials such as reinforced nylon or stainless steel are preferable. These materials offer resilience against environmental stressors, thereby extending the lifespan of the drag chain and minimizing downtime.

Another critical aspect is proper installation and maintenance. Incorrect installation can lead to premature wear or system failure. It’s essential to ensure that the drag chain is not twisted and that cables are appropriately laid within the carrier. Regular inspection and maintenance schedules can preempt failures, ensuring continuous operation. In my experience, companies that adhere to a rigorous maintenance regime experience fewer interruptions and extend the service life of their drag chains.

Advanced technologies like smart drag chains are emerging, equipped with sensors to monitor wear and performance in real-time. These innovations present a leap forward in predictive maintenance, allowing operators to address issues before they lead to failure. Companies adopting these smart solutions report reduced operational costs and improved uptime, a testament to the importance of staying at the forefront of technological advancements.

drag chain

Furthermore, in terms of scalability, choosing the right drag chain can make a substantial difference. My extensive work in scaling automation systems highlights that a modular drag chain design allows manufacturers to accommodate future expansions without a complete system overhaul. This adaptability is crucial for industries facing dynamic changes in production demands.

Experts advocate for consulting with experienced suppliers who can provide bespoke solutions tailored to specific operational requirements. Select suppliers who offer comprehensive technical support and are open to collaboration, as this relationship is central to ensuring optimal performance.

Trustworthiness in drag chain deployment also comes from thorough testing and compliance with industry standards. I recommend partnering with suppliers that have a proven track record of quality assurance and are compliant with international standards such as ISO and RoHS. These certifications are not just paper achievements but a guarantee of product reliability and safety.

In conclusion, leveraging expertise and embracing technological advancements in drag chain systems can dramatically enhance production capabilities and reliability. For manufacturers looking to stay competitive, investing in high-quality, expertly-installed, and well-maintained drag chains is not just an option but a necessity. Trust and partnership with knowledgeable suppliers will pave the way for sustained operational success and innovation in the evolving industrial landscape.