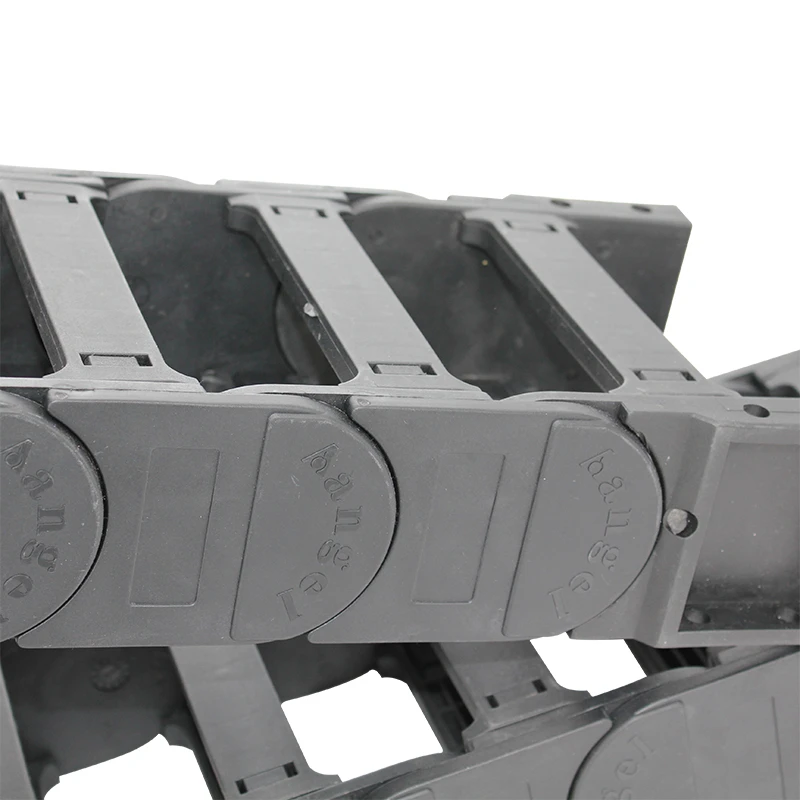

25*75 mm MTK reinforced bridge type both side openable energy chain

Drag chains are crucial components often underappreciated until a system breakdown underscores their importance. They serve as protective conveyor belts for cables and hoses, ensuring smooth operation and preventing costly downtime. As the reliance on complex machinery grows across industries such as robotics, manufacturing, and automation, understanding the nuances of drag chains can profoundly impact operational efficiency and safety.

Safety is another critical domain where drag chains play a vital role. By neatly organizing and securing cables and hoses, they prevent these components from becoming hazards that could lead to accidents or equipment damage. In environments like automotive plants or industrial assembly lines, where human-machine interaction is frequent, such safety measures are not just beneficial but essential. The reassurance of a well-managed cable system reduces the likelihood of faults or accidents, fostering a safer workspace. Purchasing decisions should derive from a place of informed expertise, not just theoretical knowledge. Collaborating with reputable manufacturers who not only understand the product but also the specific needs of your industry can greatly enhance the decision-making process. Across industries, testimonials and case studies consistently reinforce the value of engaging with experts who provide bespoke drag chain solutions tailored to specific operational demands. Moreover, adapting to new technologies and industry trends can revolutionize the use of drag chains. As the landscape shifts towards smarter and more connected devices, the integration of sensors in drag chains could offer predictive maintenance by monitoring wear and tear, offering insights into performance and lifespan. Such innovations augment the chains' functionality, ensuring they are not just passive components but active contributors to system efficiency. An awareness of these factors highlights the multifaceted role drag chains play in not only protecting but also enhancing industrial operations. Their selection and implementation can significantly influence operational efficiency, safety, and cost-effectiveness. Consequently, prioritizing informed and strategic choices in drag chain selection and maintenance can offer substantial long-term benefits for any project relying on precision and reliability in machinery operation.

Safety is another critical domain where drag chains play a vital role. By neatly organizing and securing cables and hoses, they prevent these components from becoming hazards that could lead to accidents or equipment damage. In environments like automotive plants or industrial assembly lines, where human-machine interaction is frequent, such safety measures are not just beneficial but essential. The reassurance of a well-managed cable system reduces the likelihood of faults or accidents, fostering a safer workspace. Purchasing decisions should derive from a place of informed expertise, not just theoretical knowledge. Collaborating with reputable manufacturers who not only understand the product but also the specific needs of your industry can greatly enhance the decision-making process. Across industries, testimonials and case studies consistently reinforce the value of engaging with experts who provide bespoke drag chain solutions tailored to specific operational demands. Moreover, adapting to new technologies and industry trends can revolutionize the use of drag chains. As the landscape shifts towards smarter and more connected devices, the integration of sensors in drag chains could offer predictive maintenance by monitoring wear and tear, offering insights into performance and lifespan. Such innovations augment the chains' functionality, ensuring they are not just passive components but active contributors to system efficiency. An awareness of these factors highlights the multifaceted role drag chains play in not only protecting but also enhancing industrial operations. Their selection and implementation can significantly influence operational efficiency, safety, and cost-effectiveness. Consequently, prioritizing informed and strategic choices in drag chain selection and maintenance can offer substantial long-term benefits for any project relying on precision and reliability in machinery operation.