10*15 mm MT small size mini nylon drag chain

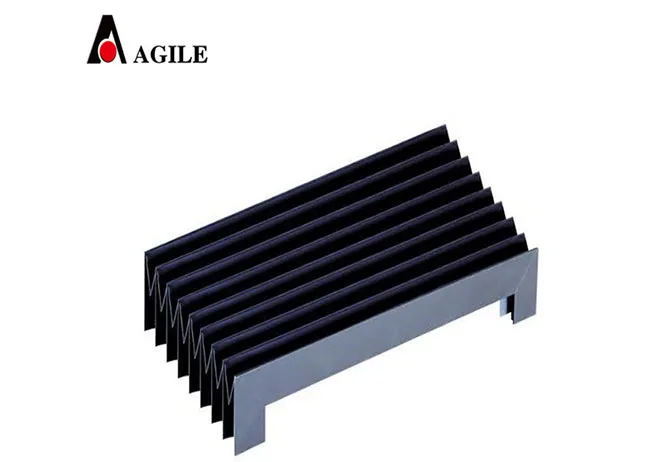

For enthusiasts and professionals seeking efficient cable management solutions, the drag chain, particularly in the size 10x20, is an innovation worth exploring. Drag chains, also known as cable carriers, play a crucial role in ensuring the safety and longevity of cables in various industrial and mechanical settings. The specific dimensions of 10x20 mm make this drag chain particularly versatile for numerous applications while maintaining a compact size.

Authoritativeness in the manufacturing of drag chains often stems from attention to design and engineering excellence. The 10x20 drag chain’s design priorities include easy assemblage and optimal performance under stress. Companies that invest in engineering precision, ensuring each link of the drag chain offers seamless movement and reduced abrasion, build trust among their clientele. Moreover, reliable manufacturers conduct thorough testing to meet industry standards. This involves stress-tests that simulate real-world conditions, confirming that the drag chain can handle the specified loads and movement cycles over extended periods without failure. Trustworthiness, a vital metric in choosing the correct supplier for drag chains, hinges upon the reputation of the manufacturer and user endorsements. Leading brands in the drag chain market provide extensive documentation, including load capacity charts and installation guides, fostering user confidence. Additionally, user testimonials and case studies, particularly from industrial sectors that heavily rely on automation, frequently cite the reliability and efficacy of the 10x20 drag chain in enhancing operational efficiency. Collaborating with suppliers that offer warranties and post-purchase support further emphasizes their commitment to product dependability. The precision and utility of the 10x20 drag chain have established this product as a cornerstone in sophisticated cable management solutions. Its integration into machinery assures users of secure and organized cabling, which in turn reduces downtime and maintenance costs. Users seeking to optimize their setups will find that investing in a well-engineered drag chain pays dividends in elevating the reliability of their machinery. As technology advances, the role of robust cable management solutions like the drag chain will only become more prominent, underscoring the importance of choosing the right component for every industrial requirement.

Authoritativeness in the manufacturing of drag chains often stems from attention to design and engineering excellence. The 10x20 drag chain’s design priorities include easy assemblage and optimal performance under stress. Companies that invest in engineering precision, ensuring each link of the drag chain offers seamless movement and reduced abrasion, build trust among their clientele. Moreover, reliable manufacturers conduct thorough testing to meet industry standards. This involves stress-tests that simulate real-world conditions, confirming that the drag chain can handle the specified loads and movement cycles over extended periods without failure. Trustworthiness, a vital metric in choosing the correct supplier for drag chains, hinges upon the reputation of the manufacturer and user endorsements. Leading brands in the drag chain market provide extensive documentation, including load capacity charts and installation guides, fostering user confidence. Additionally, user testimonials and case studies, particularly from industrial sectors that heavily rely on automation, frequently cite the reliability and efficacy of the 10x20 drag chain in enhancing operational efficiency. Collaborating with suppliers that offer warranties and post-purchase support further emphasizes their commitment to product dependability. The precision and utility of the 10x20 drag chain have established this product as a cornerstone in sophisticated cable management solutions. Its integration into machinery assures users of secure and organized cabling, which in turn reduces downtime and maintenance costs. Users seeking to optimize their setups will find that investing in a well-engineered drag chain pays dividends in elevating the reliability of their machinery. As technology advances, the role of robust cable management solutions like the drag chain will only become more prominent, underscoring the importance of choosing the right component for every industrial requirement.