Efficient Cable Management Solutions with Drag Chain Cable Carriers for Industrial Applications

Understanding Drag Chain Cable Carriers A Comprehensive Overview

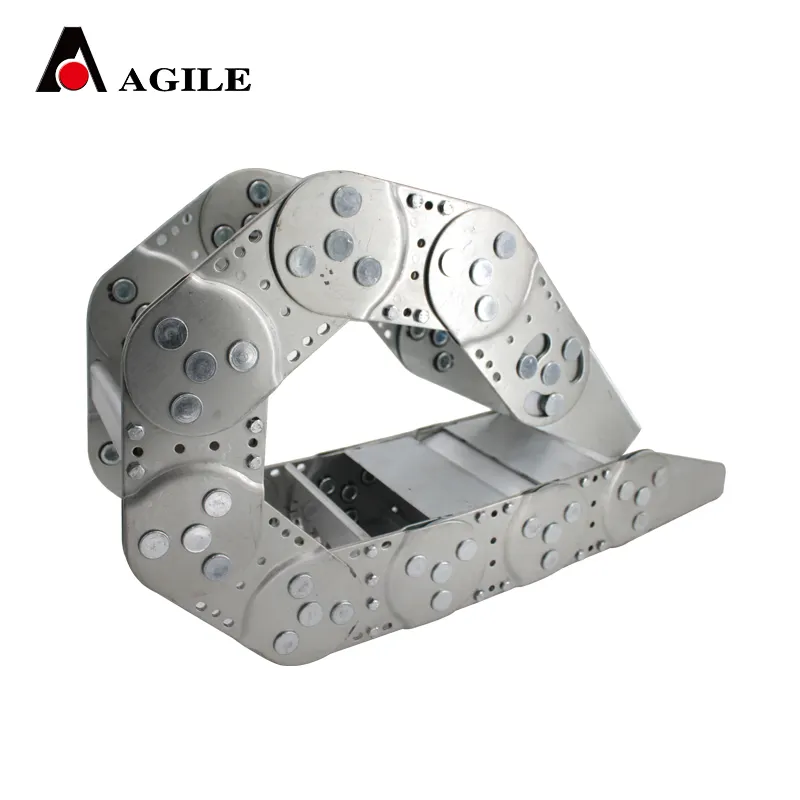

Drag chain cable carriers, also known as cable tracks or cable carriers, are essential components in various industries that involve mechanical and electrical systems. These devices are designed to organize and protect cables and hoses, ensuring smooth movement and reducing wear and tear over time. This article explores the importance, components, types, and applications of drag chain cable carriers.

Importance of Drag Chain Cable Carriers

In environments where machinery moves in multiple directions, such as robotics, machine tools, and conveyor systems, maintaining a clean and efficient workspace is crucial. Drag chain cable carriers provide an effective solution by enclosing and guiding cables and hoses, preventing them from tangling or becoming damaged. This organization not only enhances operational efficiency but also significantly reduces the risk of downtime due to cable failure. Furthermore, drag chains contribute to safety by minimizing tripping hazards that exposed cables might pose.

Components of Drag Chain Cable Carriers

A typical drag chain cable carrier consists of several key components

1. Chain Links These are the primary structure of the drag chain and are typically made from robust materials like plastic or metal. The links interconnect to form a flexible channel that can bend around corners and curves while maintaining strength.

2. End Connectors These connectors allow the cable carrier to attach to the moving machinery and provide a secure point for the beginning and end of the system.

3. Internal Dividers Many drag chain cable carriers feature internal dividers or sections that help organize different types of cables or hoses. This ensures that electrical cables remain separated from hydraulic or pneumatic lines, minimizing interference and potential damage.

4. Guide Plates Some carriers include guide plates that help support the cables within the chain, promoting smoother movement and reducing friction.

Types of Drag Chain Cable Carriers

There are several types of drag chain cable carriers available, each designed for specific applications and environments

1. Plastic Drag Chains Lightweight and corrosion-resistant, plastic chains are suitable for indoor applications with moderate loads. They are commonly seen in automation equipment and CNC machines.

drag chain cable carrier

2. Metal Drag Chains These carriers are more robust and can handle heavier loads and aggressive environments. Metal options are ideal for applications that involve high temperatures or exposure to chemicals.

3. Retractable Cable Carriers Incorporating a retractable feature, these carriers allow cables to be pulled out and retracted easily, making them ideal for portable machinery or tools.

4. Specialized Chains Some manufacturers offer customized drag chains designed to meet specific needs, such as particular cable sizes, environments, or motion patterns.

Applications of Drag Chain Cable Carriers

The versatility of drag chain cable carriers allows them to be utilized in a broad range of industries, including

1. Manufacturing In automated manufacturing environments, drag chains guide power and control cables, ensuring that essential connections remain secure as machinery moves.

2. Robotics Robot arms and automated guided vehicles frequently use cable carriers to manage power and control lines, allowing for flexible and unobstructed movement.

3. Construction Heavy machinery, such as cranes and excavators, often employ heavy-duty cable carriers to keep hydraulic lines and power cables organized and safe.

4. Food Industry In food processing plants, hygienic and durable cable carriers are essential to manage cables safely in cleanroom environments.

5. Aerospace Drag chains are used in various applications within the aerospace industry, helping support the demanding requirements of aircraft systems.

Conclusion

Drag chain cable carriers play a pivotal role in maintaining operational efficiency and safety across several industries. By organizing and protecting cables and hoses, they enable smoother operation of machinery while reducing maintenance costs and downtime. Understanding their components, types, and applications can help businesses select the right drag chain solutions for their specific needs, leading to enhanced productivity and reliability in their operations. Embracing the advantages of drag chain cable carriers is a step toward a more organized and efficient workflow in an increasingly competitive environment.