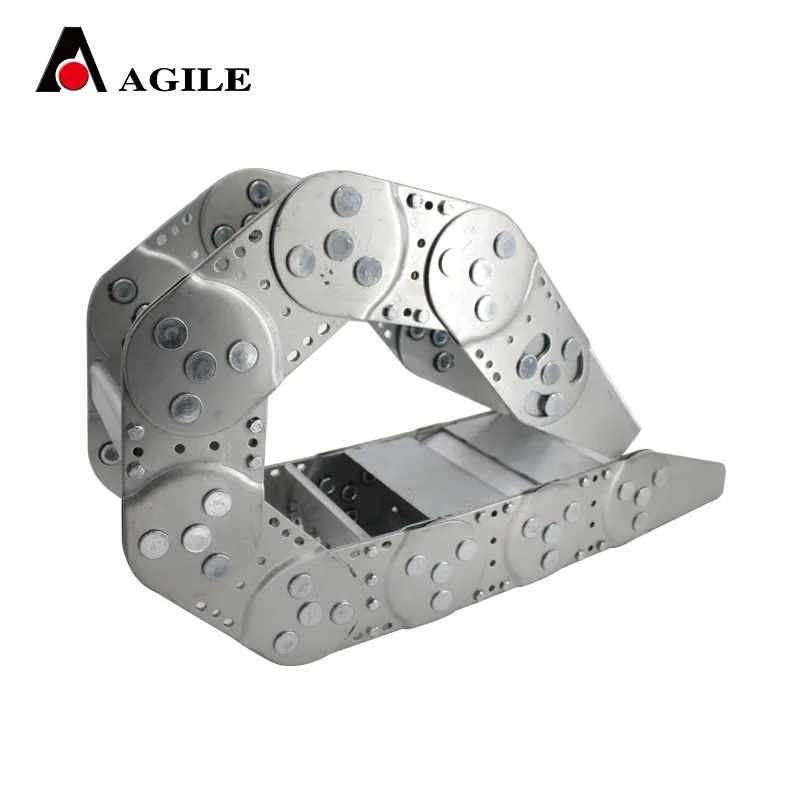

reinforced drag chain

Drag chain systems hold a significant place in various industries by ensuring the proper management of cables and hoses, which in turn maintains the efficiency of automated processes. For businesses relying heavily on automated machinery, selecting a drag chain compatible system can significantly enhance operational capabilities and reduce maintenance costs, thereby boosting productivity. This article will provide insights drawing on experience and expertise to highlight why opting for drag chain compatible solutions is vital.

Trustworthiness in selecting the right drag chain compatible system is non-negotiable, especially when high-stakes automated environments are involved. The long-term reliability of these systems can prevent costly downtime and ensure continuous operation. Businesses should rely on credible suppliers known for stringent quality checks and robust product testing. Partnering with manufacturers that offer comprehensive support services, such as installation guidance and ongoing technical support, also enhances trustworthiness. Equally important is the emphasis on maintaining a proactive maintenance schedule for drag chain systems. Experienced users leverage regular inspections to monitor the wear levels of these systems, allowing for timely intervention before any major failure occurs. This proactive approach is supported by data-driven insights from condition monitoring technologies, which offer predictive maintenance cues. A practical example can be found in the automotive industry, where drag chain systems streamline cable management in robotic arms performing repetitive tasks such as welding and assembly. Here, flexibility and reliability are paramount due to the constant movement of machinery. Drag chains that cater to the specific environmental requirements—such as resistance to weld splatter and the ability to function smoothly under rapid movement—have proven transformative. In conclusion, opting for a drag chain compatible system is not merely an operational consideration but a strategic decision that significantly impacts productivity and reliability. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can make informed choices that align with their operational objectives. Comprehensive research and selection of the right drag chain system will deliver substantial benefits, culminating in enhanced performance and reduced operational risks.

Trustworthiness in selecting the right drag chain compatible system is non-negotiable, especially when high-stakes automated environments are involved. The long-term reliability of these systems can prevent costly downtime and ensure continuous operation. Businesses should rely on credible suppliers known for stringent quality checks and robust product testing. Partnering with manufacturers that offer comprehensive support services, such as installation guidance and ongoing technical support, also enhances trustworthiness. Equally important is the emphasis on maintaining a proactive maintenance schedule for drag chain systems. Experienced users leverage regular inspections to monitor the wear levels of these systems, allowing for timely intervention before any major failure occurs. This proactive approach is supported by data-driven insights from condition monitoring technologies, which offer predictive maintenance cues. A practical example can be found in the automotive industry, where drag chain systems streamline cable management in robotic arms performing repetitive tasks such as welding and assembly. Here, flexibility and reliability are paramount due to the constant movement of machinery. Drag chains that cater to the specific environmental requirements—such as resistance to weld splatter and the ability to function smoothly under rapid movement—have proven transformative. In conclusion, opting for a drag chain compatible system is not merely an operational consideration but a strategic decision that significantly impacts productivity and reliability. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can make informed choices that align with their operational objectives. Comprehensive research and selection of the right drag chain system will deliver substantial benefits, culminating in enhanced performance and reduced operational risks.