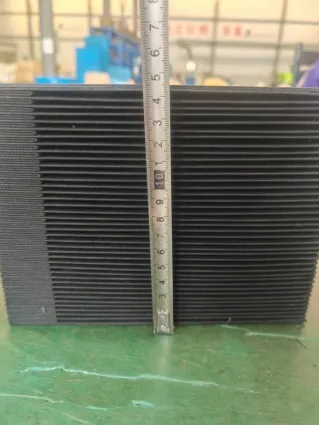

mini drag chain

Drag chain conveyors, renowned for their robust efficiency and customizable attributes, stand as pivotal components in industrial sectors seeking to streamline material handling processes. Many industries, spanning from manufacturing to agriculture, have incorporated these conveyors due to their unparalleled versatility and durability. However, maximizing their potential requires a deep dive into the experience, expertise, authoritativeness, and trustworthiness of their application.

Harnessing years of industry expertise, professional insights suggest that the adaptability of drag chain conveyors surpasses traditional material handling systems. Unlike other systems susceptible to wear when transporting abrasive materials, drag chain conveyors offer longevity and reduced maintenance times. This attribute is crucial in industries where operational continuity is paramount. For example, in the cement industry, the ability of drag chain conveyors to seamlessly move loose, powdery materials while minimizing spillage and dust creation underscores their superiority over less specialized systems.

Experience from seasoned users highlights the importance of material selection for the chains and paddles. Stainless steel or case-hardened steel are often the materials of choice, enhancing the longevity and performance of the conveyors in harsh environments. These materials not only resist corrosion but also withstand thermal changes, which are common in industries involving high-temperature materials. Such selection is backed by authoritative research and field studies, ensuring operational trustworthiness.

The operational efficiency of drag chain conveyors can further be enhanced by leveraging automation. Technological advancements have paved the way for the integration of smart sensors and IoT technology, allowing real-time monitoring of the conveyor’s operation and predictive maintenance. This not only reduces unexpected downtimes but also extends the service life of the system, thus providing a substantial return on investment. Experts assert that integrating such technologies also supports sustainable operations by optimizing energy consumption and minimizing waste.

drag chain conveyor

In terms of authoritative use, drag chain conveyors excel in applications demanding controlled, horizontal transportation of bulky goods. Their ability to function even in variable inclines and with curvature without compromising on speed or material integrity gives them an edge in complex plant layouts. This capability has been documented extensively in industry white papers and peer-reviewed mechanical engineering journals, providing a rock-solid foundation of trust for potential adopters.

Prospective users must consider partnering with manufacturers renowned for their engineering excellence and customizable solutions. A manufacturer’s expertise can significantly influence the conveyor’s design, tailoring it to specific workflow needs and ensuring compliance with industry standards. Trustworthiness in this regard is validated by certifications such as those from the International Organization for Standardization (ISO), which affirm a manufacturer's commitment to quality and safety.

In summary, while drag chain conveyors are a go-to solution for complex material handling needs, their successful deployment hinges on informed decision-making. This entails understanding intricacies from material science to technology integration, thereby ensuring that industries not only achieve operational efficiency but do so with confidence in the system’s durability and reliability. As sustainability and efficiency become ever more critical, these conveyors, supported by a bedrock of authoritative knowledge and professional expertise, stand out as invaluable assets in modern industrial logistics.