Effective Solutions with Drag Chain Conveyors

For industries reliant on efficient material handling, the drag chain conveyor emerges as a crucial asset. This robust solution is designed to transport a multitude of materials seamlessly, offering unmatched reliability and versatility. Built with either single or multiple chains, drag chain conveyors effectively move materials by pulling them through a channel, making them ideal for heavy, abrasive, and hot materials often found in mining, construction, and manufacturing sectors.

The drag chain conveyor thrives in environments where traditional conveying systems might falter. Its ability to handle large volumes at various angles with minimized spillage marks its superiority. The conveyor’s chain-driven mechanism ensures materials are not only transported horizontally but can also be elevated or declined without losing integrity. This adaptability enhances operational efficiency in facilities that need to conserve space while maximizing throughput.

When selecting a drag chain conveyor, expertise in understanding the material properties is imperative. Different materials demand varying construction features—abrasive materials might require case-hardened chains, while corrosive substances necessitate stainless steel components. Tailoring the conveyor to fit specific material characteristics not only prolongs its lifespan but also ensures consistent performance, embodying both expertise and authoritative configuration of material handling systems.

Durability is another hallmark, with drag chain conveyors engineered to withstand the most demanding operational challenges. This endurance is a testimony to their structural integrity, often reinforced by heat-treated components and sealed bearings that reduce maintenance needs. The longevity of these conveyors provides a trustworthiness that industries rely on, ensuring that the systems operate smoothly over time without unexpected failures.

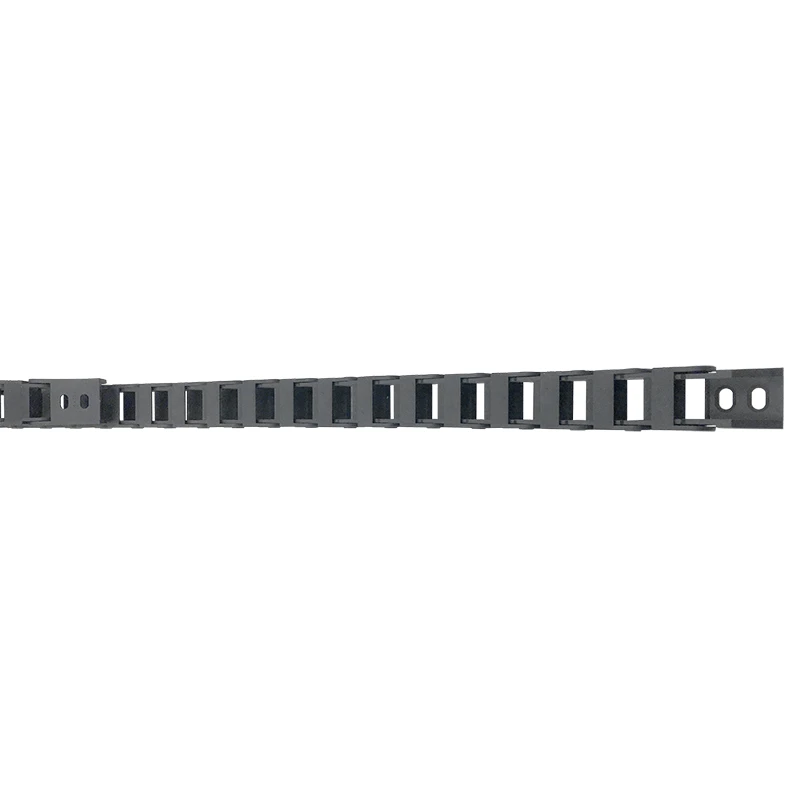

drag chain conveyor

Installation and transitioning to a drag chain conveyor system can be seamlessly executed by experienced professionals who understand the nuances of conveying technology. Their expertise ensures minimal downtime and optimal integration with existing facilities, thereby enhancing productivity. Professional installers leverage their authoritative knowledge to customize systems that meet unique logistical demands, whether it’s integrating with automated systems or scaling for increased production.

Beyond logistics, environmental considerations highlight the drag chain conveyor’s merits. Unlike pneumatic systems that consume significant energy, drag chain conveyors offer a more energy-efficient solution, reducing the overall carbon footprint of operations. This energy savings is not only economical but aligns with global sustainability goals, reflecting a trustworthy approach to modern industrial processes.

The profound impact of these conveyors is further underscored by the real-world experiences shared by businesses across industries. Many testify to the reduced operational costs and increased output after implementing drag chain systems. This real-world feedback enhances the conveyor's reputation as a credible and authoritative solution in material handling.

In conclusion, drag chain conveyors embody an intersection of experience, expertise, authority, and trust—key pillars that define their value in industrial operations. Their strategic design and flexibility meet the rigorous demands of modern industries, offering a reliable transport solution that economizes space, energy, and costs. Whether accommodating complex industrial environments or integrating into existing processes, drag chain conveyors unequivocally set the benchmark for current and future material conveying solutions.