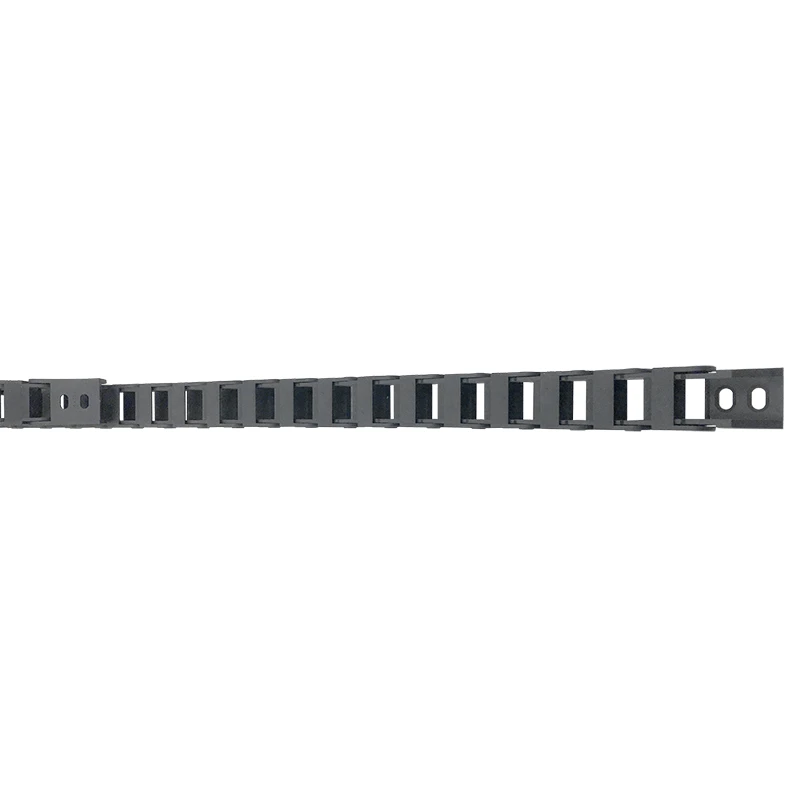

10*15 mm MT small size mini nylon drag chain

In the vast and intricate world of industrial hardware, drag chain links stand out as vital components that ensure smooth operation in various mechanical systems. Their significance, often overshadowed by more visible machinery parts, becomes apparent when understanding their crucial role in protecting cabling and hoses from everyday wear and tear.

Highlighting a real-world example can further emphasize the power of these understated components. Consider a high-speed packaging facility where rapid and precise motion is paramount. The implementation of drag chain links allows the machinery to achieve desired speed without the frequent issue of cable entanglement or degradation—a problem that previously caused significant stoppages. This firsthand experience showcases the value of these components in maintaining a smooth and efficient workflow. In product selection, relying on expert manufacturers with a profound understanding of material science and mechanical engineering ensures that the drag chain links meet specific operational needs. Trusted suppliers often provide tailored solutions, addressing unique challenges faced by different industries, such as exposure to corrosive substances or extreme temperatures. Furthermore, the advancement in technology has propelled the development of self-cleaning and low-noise drag chain links, catering to industries where hygiene and noise pollution are critical concerns. The continual improvement and specialization of these products highlight the expertise embedded in their evolution, reflecting a sophisticated understanding of complex operational demands. In conclusion, drag chain links, while often overlooked, represent a marriage of experience and expertise, delivering critical operational benefits across numerous industries. Their authority and trustworthiness are reinforced through rigorous testing and continued innovation, ensuring they remain a cornerstone in mechanical system design. Whether in robotics, manufacturing, or any field requiring dynamic cable management, the drag chain link stands as a testament to engineering ingenuity and reliability, demonstrating that even the most unassuming components can have a significant impact on operational success.

Highlighting a real-world example can further emphasize the power of these understated components. Consider a high-speed packaging facility where rapid and precise motion is paramount. The implementation of drag chain links allows the machinery to achieve desired speed without the frequent issue of cable entanglement or degradation—a problem that previously caused significant stoppages. This firsthand experience showcases the value of these components in maintaining a smooth and efficient workflow. In product selection, relying on expert manufacturers with a profound understanding of material science and mechanical engineering ensures that the drag chain links meet specific operational needs. Trusted suppliers often provide tailored solutions, addressing unique challenges faced by different industries, such as exposure to corrosive substances or extreme temperatures. Furthermore, the advancement in technology has propelled the development of self-cleaning and low-noise drag chain links, catering to industries where hygiene and noise pollution are critical concerns. The continual improvement and specialization of these products highlight the expertise embedded in their evolution, reflecting a sophisticated understanding of complex operational demands. In conclusion, drag chain links, while often overlooked, represent a marriage of experience and expertise, delivering critical operational benefits across numerous industries. Their authority and trustworthiness are reinforced through rigorous testing and continued innovation, ensuring they remain a cornerstone in mechanical system design. Whether in robotics, manufacturing, or any field requiring dynamic cable management, the drag chain link stands as a testament to engineering ingenuity and reliability, demonstrating that even the most unassuming components can have a significant impact on operational success.