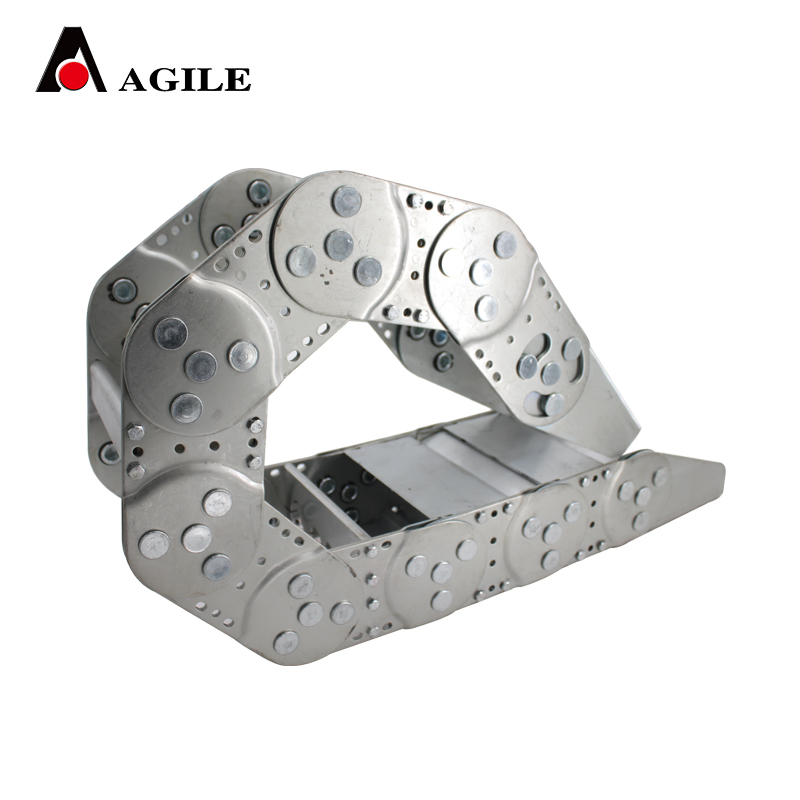

reinforced drag chain

Navigating the intricate landscape of drag chain suppliers requires an informed approach that balances experience, expertise, authoritativeness, and trustworthiness. These qualities are not merely advantageous; they are essential for ensuring product quality and supplier reliability. As industries increasingly rely on automation and precision engineering, drag chains—also known as cable carriers—play a critical role in safeguarding cables, hoses, and other flexible conduits from damage and wear.

Understanding the engineering dynamics behind drag chains further enhances one’s ability to select the right supplier. Drag chains must withstand different types of stress—tensile, compressive, and shear—while maintaining flexibility. They serve critical functions protecting cables from harsh environments, reducing mechanical load on moving cables, and prolonging the lifespan of connected devices by preventing unnecessary wear. Therefore, the choice of material—whether abrasion-resistant nylons for light applications or tempered steel for heavy industrial use—should be influenced by the supplier's adeptness in these areas. Moreover, the engineering support offered by suppliers can dramatically influence project outcomes. This includes assistance in installation and maintenance practices, which are crucial for preventing downtime and preserving equipment integrity. The ability to provide digital modeling and simulations of drag chain implementations allows clients to anticipate interactions with their machinery, preemptively addressing any fitment or movement challenges. Engaging with drag chain suppliers should not be reduced to mere transactional exchanges. Instead, forming a strategic partnership can lead to innovative solutions that drive productivity and efficiency. Hence, prioritizing suppliers that offer ongoing education, updates on technological advancements, and insight into emerging trends is prudent. As industries evolve and demands increase, the role of drag chain suppliers will continue to expand, necessitating an informed selection process. By prioritizing experience, expertise, authoritativeness, and trustworthiness, businesses can secure not only a product but a partner capable of adapting to future challenges and technologies. Therefore, prudent research coupled with a strategic approach can yield significant dividends in operational efficiency and product longevity.

Understanding the engineering dynamics behind drag chains further enhances one’s ability to select the right supplier. Drag chains must withstand different types of stress—tensile, compressive, and shear—while maintaining flexibility. They serve critical functions protecting cables from harsh environments, reducing mechanical load on moving cables, and prolonging the lifespan of connected devices by preventing unnecessary wear. Therefore, the choice of material—whether abrasion-resistant nylons for light applications or tempered steel for heavy industrial use—should be influenced by the supplier's adeptness in these areas. Moreover, the engineering support offered by suppliers can dramatically influence project outcomes. This includes assistance in installation and maintenance practices, which are crucial for preventing downtime and preserving equipment integrity. The ability to provide digital modeling and simulations of drag chain implementations allows clients to anticipate interactions with their machinery, preemptively addressing any fitment or movement challenges. Engaging with drag chain suppliers should not be reduced to mere transactional exchanges. Instead, forming a strategic partnership can lead to innovative solutions that drive productivity and efficiency. Hence, prioritizing suppliers that offer ongoing education, updates on technological advancements, and insight into emerging trends is prudent. As industries evolve and demands increase, the role of drag chain suppliers will continue to expand, necessitating an informed selection process. By prioritizing experience, expertise, authoritativeness, and trustworthiness, businesses can secure not only a product but a partner capable of adapting to future challenges and technologies. Therefore, prudent research coupled with a strategic approach can yield significant dividends in operational efficiency and product longevity.