drag chain use

The Essentials of Drag Chain Use in Industrial Applications

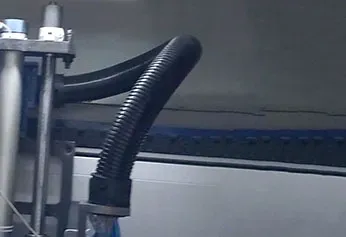

Drag chains, also known as cable carriers or energy chains, are vital components in various industrial applications, particularly in automated machinery and robotic systems. These systems often require a reliable method for managing cables and hoses that supply power and data, allowing for smooth, uninterrupted movement in dynamic environments. This article will explore the importance of drag chains, their functionality, advantages, and considerations for optimal use.

Understanding Drag Chains

A drag chain is a flexible and robust structure designed to hold and protect cables and hoses as they move with machinery. Drag chains are typically made from durable materials such as plastics or metal, designed to withstand wear and tear. They consist of a series of linked sections that create a path for cables and hoses to follow, reducing the risk of tangling, abrasion, and wear from repetitive motion.

Key Benefits of Drag Chains

1. Cable Protection One of the primary advantages of using drag chains is the protection they provide. Cables and hoses can easily be damaged when exposed to mechanical movement, heat, or environmental factors. Drag chains encapsulate these elements, ensuring they remain intact and function correctly.

2. Organization In industrial settings, order is crucial. Drag chains help organize cables and hoses, making it easier to identify, maintain, and replace them as needed. A well-organized setup reduces the risk of operational delays caused by tangled or damaged cables.

3. Enhanced Mobility Drag chains facilitate smooth movement of machines. By guiding cables and hoses in a well-defined path, they allow for greater freedom of motion without impeding the machinery's operation. This is especially important in automated systems, where precise movements are essential for productivity.

4. Reduced Maintenance Costs Preventive maintenance is significantly easier with drag chains. By protecting cables and hoses and keeping them organized, businesses can reduce downtime and maintenance costs. This translates to increased operational efficiency and cost savings over time.

drag chain use

5. Versatility Drag chains are versatile and can be tailored to various industrial applications. They come in different sizes and configurations, accommodating a wide range of electrical and hydraulic systems. This adaptability ensures that businesses in different sectors can leverage the benefits of drag chains.

Considerations for Optimal Use

When integrating drag chains into an industrial setup, several factors should be considered to maximize their effectiveness

1. Selection of Material The material of the drag chain should be chosen based on the specific environment it will be used in. For instance, chains in high-temperature environments should be made from heat-resistant materials, while those exposed to chemicals or abrasion may require special coatings or metal construction.

2. Sizing and Design Proper sizing is crucial. The drag chain must be appropriate for the number and type of cables or hoses it will carry. An inadequate size can lead to abrasion, while oversized chains can become cumbersome and affect the machine's operation.

3. Preventive Maintenance Although drag chains significantly reduce the need for maintenance, regular inspections are still essential. Checking for wear and tear, ensuring that cables are secure, and confirming that the chains are functioning correctly can prevent unexpected failures.

Conclusion

Drag chains are a fundamental component in modern industrial applications, offering protection, organization, and enhanced mobility for cables and hoses. Their ability to reduce maintenance costs and improve efficiency makes them invaluable in automated environments. By selecting the right material and size and committing to regular preventive maintenance, businesses can maximize the benefits of drag chains, ensuring smooth operation and longevity of their machinery. Embracing drag chain technology is a proactive step toward improving operational efficiency and safeguarding vital equipment in any industrial setting.